Microstepping Stepper Motor Driver Kit. This page is for theory of operation

only. For operation instructions see the Users Guide

and for instructions to build it, see the

Assembly Manual.

How it Works

History.

Cheap microstepping drivers seemed to be nonexistant.

I quickly made up a board that would suit my hobby needs and be

able to drive most motors fairly accurately and powerfully,

with cheap non-specialist parts (no stepper ICs).

Block Diagram;

+5v to +32v --------------------,

(depends on motor and |

what speeds required) |

|

| motor common (power) wire

| (motor must have 5,6,8 wires)

,---------*-------,

| |

,---*---, ,----*----,

| | | |

| | | |

| | | |

# # # # 4 motor coils

A+ | A- | B+ | B- | (arranged as 2 phases

| | | | unipolar)

| | | |

+5v----, | | | |

| C C C C 4 darlington power

brain-->---B --B --B --B transistors

| E E E E

| | | | |

^ | | | |

| '---*---' '----*----'

| | | 2 current-sense

'-------<---- Rs <-- Rs resistors, one for

| | each phase

| |

gnd -----------------*-----------------*-------------------

Basic design

It is a unipolar (or 5-wire type) driver. The motor must have

5 or 6 wires (or 8), as 4-wire motors are only for bipolar

and 4-WIRE MOTORS WILL NOT WORK WITH THIS BOARD.

The constant current system is crude but simple, it relies on

setting the base of the main transistors at a "set" level, then

this causes a "set" voltage across the sense resistor Rs, ie

maintains constant current. It does get some temp drift with

large currents, but it's simple and accurate enough with the

resistor values i've tested. It actually works quite well!

The brain has control of which of the 4 transistors are ON,

and sets 3 possible current levels, enough to do 6th stepping

and give 1200 steps/rev with hardware alone. The software I

have provided also will do pwm and give 18th stepping, which

is 3600 steps/rev, almost stepless operation.

The PIC has plenty of left over rom if you need to do motion

control or use the board as the complete brains and driver for

an entire machine. Up to 9 PIC in/out pins can be allocated to

the board.

Special Features

There is an RC filter in the linear microstepping circuitry that

will give fairly smooth "ramping" from one current level to the

next. At tuned speed this gives almost "sine like" smoothness and

quietness.

In all lower speeds, the linear current ramping does still have

some effect and ramps between steps more smoothly with less problems

from resonance and less ringing torque. Less ringing torque means

more available torque and quieter more powerful operation.

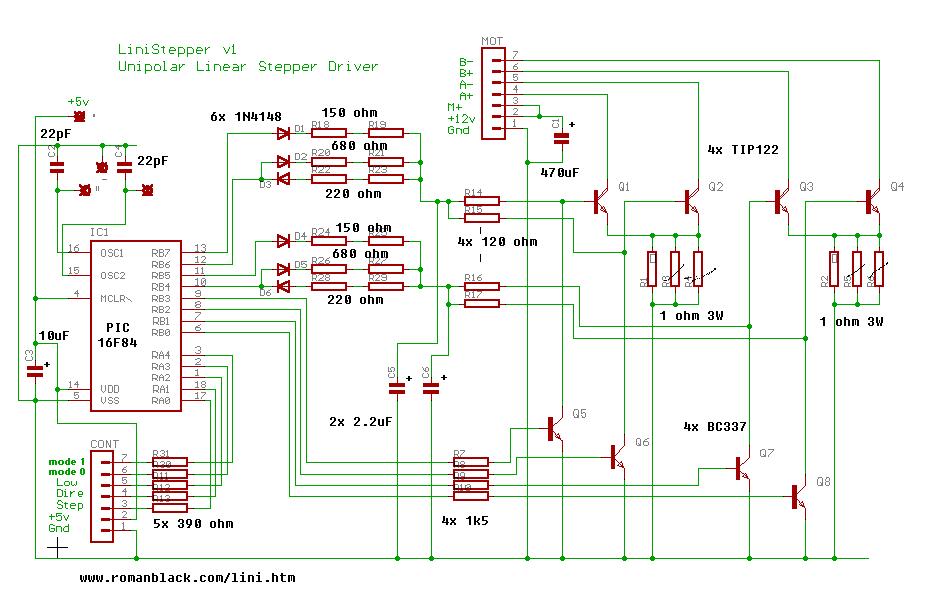

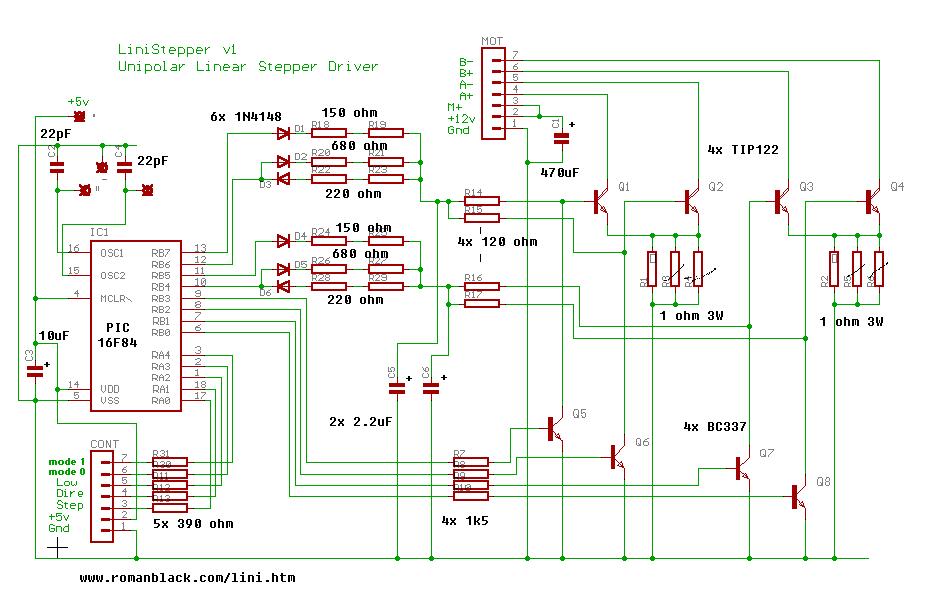

Circuit Diagram;

The circuit looks messy as it has provision to be wired in different

formats for different user requirements.

The 6th stepping needs 3 different current levels, and OFF,

and this is provided by 4 PIC outputs and some resistor ladders.

The value of resistors sets the 3 individual levels. This gives

1200 steps/rev in hardware alone, and software can modulate

between any two current levels to give "tween" steps chosen

in software. My software (supplied) does 200,400,1200,3600 steps.

C5 and C6 are the ramping capacitors.

Unipolar.

I chose this because it has advantage of making the circuit cheap

and much simpler and easier to build. Less parts, less soldering,

etc etc. Also a motor run as unipolar has half the inductance of

the bipolar wiring and can perform better at higher speeds.

It is also the configuration of most cheap "surplus" stepper

motors, etc etc.

Constant current?

Constant current is needed to set the small current levels needed

for microstepping. It also allows good high speed motor operation.

The board controls the current through the motor coils, regardless

of motor voltage or power supply voltage.

You can connect a number of different motors that have different

ohms etc, and the board will run them at the same (set) current.

The circuit looks messy as it has provision to be wired in different

formats for different user requirements.

The 6th stepping needs 3 different current levels, and OFF,

and this is provided by 4 PIC outputs and some resistor ladders.

The value of resistors sets the 3 individual levels. This gives

1200 steps/rev in hardware alone, and software can modulate

between any two current levels to give "tween" steps chosen

in software. My software (supplied) does 200,400,1200,3600 steps.

C5 and C6 are the ramping capacitors.

Unipolar.

I chose this because it has advantage of making the circuit cheap

and much simpler and easier to build. Less parts, less soldering,

etc etc. Also a motor run as unipolar has half the inductance of

the bipolar wiring and can perform better at higher speeds.

It is also the configuration of most cheap "surplus" stepper

motors, etc etc.

Constant current?

Constant current is needed to set the small current levels needed

for microstepping. It also allows good high speed motor operation.

The board controls the current through the motor coils, regardless

of motor voltage or power supply voltage.

You can connect a number of different motors that have different

ohms etc, and the board will run them at the same (set) current.

6th stepping is done in hardware

Microstepping

Uses combinations of the 3 available current levels to give 6th

stepping, or 6 times as many steps as the motor has in full-step

mode. Additional software control by the PIC gives 3600 steps!

Good for science/robot motors to move in 0.1 degree increments.

(The stepper motor itself will not position accurately down to

one 3600th of a turn, but there is still good useful positioning

and many other benefits gained from the increased smoothness.)

Microstepping has less noise, and less resonance allowing

operation to very high motor speeds. If you have only used full

step and half step drivers before you will really enjoy

microstepping. If you write custom PIC software you can get

infinite angle control by controlling the 2 motor currents with

software pwm.

Linear?

Many people don't like them, and they are definitely not

fashionable in these days of throwaway bubblejet printers with

tiny stepper chips like the UCN5804.

But, linear stepper drivers give very good MOTOR performance,

especially when you need to accelerate to high motor speeds or

need smooth "stepless" operation at very low speeds. Torque ripple

from voltage chopping is removed, also gone is the supply ripple

from chopper recirculating currents. Expensive high-speed high-

current diodes are not needed. Eddy currents and copper losses,

and recirculating diode losses are reduced and the motor gets

LESS heating with linear than with a chopper supply, although the

driver gets more. :o)

Yes this driver does get hot, and needs a heatsink!

But I designed this for my needs, ie to be adaptable to any new

motor needs I have from 200mA floppy motors that need fine

microstepping, to large 2A motors etc. I thought it was better

to have "one board does all" than to use the expensive and

tiny stepper chips.

Think "large audio amp"...

- Linear is a great way of getting an exact-shaped high freq

current into something inductive like a speaker or motor.

Current Ramping

A benefit of linear, the analog current control has an RC network,

giving a "ramp" from one current step to the next.

Ramping rate between steps is selectable by the capacitor size.

Ramping is much better than hard edged steps, and reduces

excitation energy that causes "singing" and resonance. With ramping,

more of the motor energy is converted to forward rotation, unlike

the "two steps forward one step back" effect of hard ringing steps.

The ramping can be tuned for main operating speed to give almost

stepless operation and very quiet and smooth rotation. Analog ramping

takes no PIC processor time and can be set VERY slow so even slow

motor speeds like 0.5 rps can be made smooth!

No other cheap stepper driver does this!

| | |

|-----| |------

| | |

| | |

| | |

----| |-----|

| | |

Normal stepper driver.

(jerky, overshoots, resonant, noisy, reduced torque)

/-\ /-\

/ \ / \

\ / \ / \

\ / \ /

\-/ \-/

With simple analog ramping.

(more "stepless", less overshoot, smoother better torque)

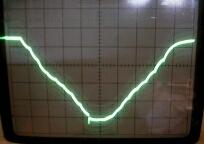

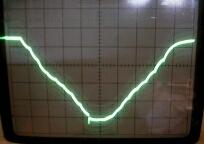

Here are the actual waveforms

(Shown is the DC current through the 2 motor phases. 1A = 2 vert div)

6th stepping is done in hardware

Microstepping

Uses combinations of the 3 available current levels to give 6th

stepping, or 6 times as many steps as the motor has in full-step

mode. Additional software control by the PIC gives 3600 steps!

Good for science/robot motors to move in 0.1 degree increments.

(The stepper motor itself will not position accurately down to

one 3600th of a turn, but there is still good useful positioning

and many other benefits gained from the increased smoothness.)

Microstepping has less noise, and less resonance allowing

operation to very high motor speeds. If you have only used full

step and half step drivers before you will really enjoy

microstepping. If you write custom PIC software you can get

infinite angle control by controlling the 2 motor currents with

software pwm.

Linear?

Many people don't like them, and they are definitely not

fashionable in these days of throwaway bubblejet printers with

tiny stepper chips like the UCN5804.

But, linear stepper drivers give very good MOTOR performance,

especially when you need to accelerate to high motor speeds or

need smooth "stepless" operation at very low speeds. Torque ripple

from voltage chopping is removed, also gone is the supply ripple

from chopper recirculating currents. Expensive high-speed high-

current diodes are not needed. Eddy currents and copper losses,

and recirculating diode losses are reduced and the motor gets

LESS heating with linear than with a chopper supply, although the

driver gets more. :o)

Yes this driver does get hot, and needs a heatsink!

But I designed this for my needs, ie to be adaptable to any new

motor needs I have from 200mA floppy motors that need fine

microstepping, to large 2A motors etc. I thought it was better

to have "one board does all" than to use the expensive and

tiny stepper chips.

Think "large audio amp"...

- Linear is a great way of getting an exact-shaped high freq

current into something inductive like a speaker or motor.

Current Ramping

A benefit of linear, the analog current control has an RC network,

giving a "ramp" from one current step to the next.

Ramping rate between steps is selectable by the capacitor size.

Ramping is much better than hard edged steps, and reduces

excitation energy that causes "singing" and resonance. With ramping,

more of the motor energy is converted to forward rotation, unlike

the "two steps forward one step back" effect of hard ringing steps.

The ramping can be tuned for main operating speed to give almost

stepless operation and very quiet and smooth rotation. Analog ramping

takes no PIC processor time and can be set VERY slow so even slow

motor speeds like 0.5 rps can be made smooth!

No other cheap stepper driver does this!

| | |

|-----| |------

| | |

| | |

| | |

----| |-----|

| | |

Normal stepper driver.

(jerky, overshoots, resonant, noisy, reduced torque)

/-\ /-\

/ \ / \

\ / \ / \

\ / \ /

\-/ \-/

With simple analog ramping.

(more "stepless", less overshoot, smoother better torque)

Here are the actual waveforms

(Shown is the DC current through the 2 motor phases. 1A = 2 vert div)

3 current levels, 1200 steps, no ramping (normal microstepping)

3 current levels, 1200 steps, no ramping (normal microstepping)

3 current levels, 1200 steps, with linear ramping!

3 current levels, 1200 steps, with linear ramping!

9 current levels, 3600 steps, with linear ramping!

That is a "sine-like" wave for almost stepless operation.

Operation of the constant current circuit:

Example: If voltage at point Vx is 2v (by the voltage divider),

Rsense is at (2v-1v)=1v.

If Rsense is 1 ohm the current is fixed at 1A as shown:

+12v dc

+5v ---------, |

| |

| |

,------, | Stepper

| | | coil

| | 4.5v out | |

| |------, | |

| | | | |

| PIC | R1 Rp |

| brain| | | |

| | | | C NPN Darlington

| | Vx *---*--B (1V b-e)

| | 2v | 2v E

| | | | 1v

| | ,--* |

| | | | |

| | C R2 R current

'------' | | | sense

'--* | 1v / 1ohm = 1amp

| |

| |

gnd ----------*--------*---------------

Also: A Java simulation of this circuit.

The capacitor across R2 gives the current ramping. No it's not

perfect ramping, but for a cheap simple solution it works ok.

With 6th stepping, the cap is always charged at the last level,

so when the step occurs the volts ramp smoothly to the next level.

Rp holds the transistor JUST off (at 0% current) when the PIC is

not sending an output, so any signal from the PIC will

proportionately increase the current past the zero point.

In this way the PIC sets 4 main currrent levels;

* 0% current

* 25% current

* 55% current

* 100% current

To make these levels tuneable I have provided a small prototype

area on the board where you can make resistance values by combining

two resistors in series. The resistor values I have chosen are to

give the currents above, give or take a few percent.

The hardware microstepping alone gives 1200 step operation.

In software the PIC can do modulation between any 2 of these levels,

giving "tween" current levels of any amount.

9 current levels, 3600 steps, with linear ramping!

That is a "sine-like" wave for almost stepless operation.

Operation of the constant current circuit:

Example: If voltage at point Vx is 2v (by the voltage divider),

Rsense is at (2v-1v)=1v.

If Rsense is 1 ohm the current is fixed at 1A as shown:

+12v dc

+5v ---------, |

| |

| |

,------, | Stepper

| | | coil

| | 4.5v out | |

| |------, | |

| | | | |

| PIC | R1 Rp |

| brain| | | |

| | | | C NPN Darlington

| | Vx *---*--B (1V b-e)

| | 2v | 2v E

| | | | 1v

| | ,--* |

| | | | |

| | C R2 R current

'------' | | | sense

'--* | 1v / 1ohm = 1amp

| |

| |

gnd ----------*--------*---------------

Also: A Java simulation of this circuit.

The capacitor across R2 gives the current ramping. No it's not

perfect ramping, but for a cheap simple solution it works ok.

With 6th stepping, the cap is always charged at the last level,

so when the step occurs the volts ramp smoothly to the next level.

Rp holds the transistor JUST off (at 0% current) when the PIC is

not sending an output, so any signal from the PIC will

proportionately increase the current past the zero point.

In this way the PIC sets 4 main currrent levels;

* 0% current

* 25% current

* 55% current

* 100% current

To make these levels tuneable I have provided a small prototype

area on the board where you can make resistance values by combining

two resistors in series. The resistor values I have chosen are to

give the currents above, give or take a few percent.

The hardware microstepping alone gives 1200 step operation.

In software the PIC can do modulation between any 2 of these levels,

giving "tween" current levels of any amount.

Questions:

-

mauda@macc.com.ps asks: "

can i used pic16f628a instead of 628"

James Newton of MassMind replies: Yes, you can.

-

mauda@macc.com.ps asks: "

Hello

i dont know how to use mplab , i used micro C

what should i do to conver the file to hex file

regards"

James Newton of MassMind replies: Compile? I'm not a Micro C user, so I don't konw. Perhaps you could talk to the nice people at Micro C about how to use their compiler.

-

-

ediestel@pol.net

asks:

I would like to use linisteppers to drive Vexta pk246 motors with encoders.

They are 3 amp/phase in unipolar mode.

When ordering the kits - 4 axis - can you provide the parts that are needed

for 3amp/phase operation as part of the kit ?

The description of use for higher amps sounds hesitant; do you advise against

it ?

Is there a detailed post from someone that runs a 3 amp/phase motor with

this card ?

James

Newton of James Newton's Massmind replies: Sorry, I can not change

the component values in the kit. But the power resistors you will need are

commonly available at any

electronics

supplier.

At 3 amps, in microstepping modes, the power transistors on the Linistepper

will get very hot. It is your responsibility to keep them cooled down enough

that they don't burn out. In full or half step, heat will be much less of

a problem.

A lot of people have run the Linistepper at 3, 4 or even 5 amps, but they

used CPU fans or very

large heatsinks and they tested it carefully under all conditions before

they left it running. All the details on how to tune it for higher amperage

are at: How to use it, and keep it

cool!

-

agalliazzo@gmail.com

asks:

If I have a look to the schematic image

http://www.piclist.com/images/member/RB-ezy-Q33/circuit.gif i see R14-R15-R16-R17

in series with the base of the four TIP122... Is it the right way to connect

these components? In the costant current explanation it seem that the resistors

should be connected to GND... Is something wrong in my idea or it's only

a second "version" of the current controller circuit?

James

Newton of James Newton's Massmind replies: The current limit resistors

are R1 and R2. R14, etc...are the control / PWM

resistors.

-

edgey01@gmail.com.au

asks:

can you explain how the sense resistors work, from the circuit it would appear

the are current limiting only, how is the pic able to sense the apms/volts?

James

Newton of James Newton's Massmind replies: The PIC regulates the current

by changing it's outputs to the analog circuit. The circuit itself reacts

to the changes in the motor and corrects the bias of the power transistors

to compensate.

-

Looks good will try it out

also see possable use as 3 phase inverter driver??

James

Newton replies: Possibly. Please let us know if it works out for

you.

-

-

-

How big must the

capicitator over r2 be???

James

Newton replies: That depends on the size of R2 and the ramp you wish

to create.

-

how to design a stepper

motor that would complete one revolution in one day(24 hrs)?

James

Newton replies: You would need an accurate timebase such as a clock,

and then a divider that would produce one step pulse every so many clock

pulses. For example, with a 1 second pulse from the clock, a 200 step /

revolution stepper motor, and the controller set for 1200 step (or 6th

microstepping) you would need to divide the clock pulse by 72 (producing

one step pulse per 72 clock pulses) in order to turn the stepper motor one

revolution per day. Since the linistepper is an open source project, if are

yourself or you have access to an experienced PIC assembly language programmer,

these functions could be added to the chip in the linistepper itself. Or

they could be developed externally in hardware or in software using existing

programmable hardware.

-

-

jacknjean@wilkins.net

asks:

Hi,

I really like your way of thinking on stepper motor control. I started out

getting involved in model railroading, but my eyes have gotten so poor at

age 66 that I decided to convert my small Myford lathe into a mill so I could

drill holes more accurately. Then I started thinking about adapting CNC to

it. This would allow me to program for repeat hole patterns etc.

What I want to know is if it is possible to adapt a 555 timer chip so I could

have manual control for a small mill job or just to have a rapid traverse?

This would also require direction control. Also, what provisions do you have

for limit switches and home position? Thanks so much. Jack

James

Newton replies: While your 555 mod should be possible, I would think

this would be better supported via the PC software. Turbo CNC and others

support joystick or mouse interfaces that run the motors under your manual

control. Limit and home switches are also best supported by the

software.

-

rmustakos@att.net

asks:

Very nice! I have a question about the tuning of the linearity of the C-R2

circuit for different stepping speeds. If I put a digital pot between the

C and the Base junction with R2, will that vary the charge time and let me

tune on the fly? R(digital pot) would vary with step time and inverse with

step size (longer time between steps == lower R, smaller steps == higher

R).

Thanks

RM

James

Newton replies: I would imagine

so...

-

-

Aldershof-MSII@Prodigy.net

asks:

Looks like what I need, but first -- a bit of guidance. I want to drive and

control, remotely, three needle valves. The inputs would be three potentiometers,

giving some kind of voltage input to your control boards. Each board would

control a stepper motor, geared or otherwise connected to a needle valve

shaft. Turning the potentiometers from zero to max. would then turn the needle

valves from fully closed to fully open.

This is obviously a low-power application, but will require fast response

and frequent changes, up and down. The system will be in continuous duty,

over a period of hours. I don't see any need for mode changes; we would

presumably set it permanently in microstepping mode.

Questions:

1. Is this feasible, as it appears to be?

2. What would be the appropriate voltage to apply across the input potentiometer,

and exactly how would that be applied to the control board inputs?

3. Recognizing that a needle valve requires several revolutions from fully

closed to fully opened, how would the input voltage range be converted into

several stepper revolutions? Would it be necessary to use gears, or can

zero-to-max input produce, say, four full stepper revolutions?

4. Am I on the wrong track here? Is there a simpler and cheaper way to accomplish

what I am trying to do?

Thanks for your advice. BTW, your presentation here seems outstanding, remarkably

complete, and very clear. The apparent quality of your kit, and the user

guidance, are excellent.

Kent

James Newton replys:

Answers by the number:

-

Sure

-

The linistepper (as is) does not respond to an

analog signal but rather to

step and direction digital inputs.

You would have to either A) Change the programming of the on board

PIC microcontroller to use an

A/D converter and read the signal then

generate step and direction commands for the existing stepper controler code,

which you CAN do because Roman has made this an open source project, or B)

build some other controler that translates the analog voltages into step

and direction commands. A PIC

or SX would be fine for doing that.

Probably even a basic stamp.

-

See the answer to #2. But there is no limit on the rotation of the steppers.

-

It depends on what you really need. I think you are looking for a

servo based system rather than

steppers, because some servos can adjust position based on an analog input

and it is easy to convert an analog input into the pulse width signal that

standard servos accept, but the cost of a servo that is strong enough will

probably be higher than the cost of a stepper and controller. Servos include

feedback (which is not usually necessary with a stepper), electronics and

gearing which increase the cost. Also, I haven't seen a servo that would

do more than about 180' (they may exist, I just haven't seen one) so that

requires gearing as you suspect. Finally, you may find that a simple 1:1

relationship between the analog input and the valve position is not what

you actually need. In that case, haveing a

microcontroller in there would allow you

to vary the valve position as you wish.

Thanks for the kind words and good luck with your project.

Comments:

Interested:

The circuit looks messy as it has provision to be wired in different

formats for different user requirements.

The 6th stepping needs 3 different current levels, and OFF,

and this is provided by 4 PIC outputs and some resistor ladders.

The value of resistors sets the 3 individual levels. This gives

1200 steps/rev in hardware alone, and software can modulate

between any two current levels to give "tween" steps chosen

in software. My software (supplied) does 200,400,1200,3600 steps.

C5 and C6 are the ramping capacitors.

Unipolar.

I chose this because it has advantage of making the circuit cheap

and much simpler and easier to build. Less parts, less soldering,

etc etc. Also a motor run as unipolar has half the inductance of

the bipolar wiring and can perform better at higher speeds.

It is also the configuration of most cheap "surplus" stepper

motors, etc etc.

Constant current?

Constant current is needed to set the small current levels needed

for microstepping. It also allows good high speed motor operation.

The board controls the current through the motor coils, regardless

of motor voltage or power supply voltage.

You can connect a number of different motors that have different

ohms etc, and the board will run them at the same (set) current.

The circuit looks messy as it has provision to be wired in different

formats for different user requirements.

The 6th stepping needs 3 different current levels, and OFF,

and this is provided by 4 PIC outputs and some resistor ladders.

The value of resistors sets the 3 individual levels. This gives

1200 steps/rev in hardware alone, and software can modulate

between any two current levels to give "tween" steps chosen

in software. My software (supplied) does 200,400,1200,3600 steps.

C5 and C6 are the ramping capacitors.

Unipolar.

I chose this because it has advantage of making the circuit cheap

and much simpler and easier to build. Less parts, less soldering,

etc etc. Also a motor run as unipolar has half the inductance of

the bipolar wiring and can perform better at higher speeds.

It is also the configuration of most cheap "surplus" stepper

motors, etc etc.

Constant current?

Constant current is needed to set the small current levels needed

for microstepping. It also allows good high speed motor operation.

The board controls the current through the motor coils, regardless

of motor voltage or power supply voltage.

You can connect a number of different motors that have different

ohms etc, and the board will run them at the same (set) current.

6th stepping is done in hardware

Microstepping

Uses combinations of the 3 available current levels to give 6th

stepping, or 6 times as many steps as the motor has in full-step

mode. Additional software control by the PIC gives 3600 steps!

Good for science/robot motors to move in 0.1 degree increments.

(The stepper motor itself will not position accurately down to

one 3600th of a turn, but there is still good useful positioning

and many other benefits gained from the increased smoothness.)

Microstepping has less noise, and less resonance allowing

operation to very high motor speeds. If you have only used full

step and half step drivers before you will really enjoy

microstepping. If you write custom PIC software you can get

infinite angle control by controlling the 2 motor currents with

software pwm.

Linear?

Many people don't like them, and they are definitely not

fashionable in these days of throwaway bubblejet printers with

tiny stepper chips like the UCN5804.

But, linear stepper drivers give very good MOTOR performance,

especially when you need to accelerate to high motor speeds or

need smooth "stepless" operation at very low speeds. Torque ripple

from voltage chopping is removed, also gone is the supply ripple

from chopper recirculating currents. Expensive high-speed high-

current diodes are not needed. Eddy currents and copper losses,

and recirculating diode losses are reduced and the motor gets

LESS heating with linear than with a chopper supply, although the

driver gets more. :o)

Yes this driver does get hot, and needs a heatsink!

But I designed this for my needs, ie to be adaptable to any new

motor needs I have from 200mA floppy motors that need fine

microstepping, to large 2A motors etc. I thought it was better

to have "one board does all" than to use the expensive and

tiny stepper chips.

Think "large audio amp"...

- Linear is a great way of getting an exact-shaped high freq

current into something inductive like a speaker or motor.

Current Ramping

A benefit of linear, the analog current control has an RC network,

giving a "ramp" from one current step to the next.

Ramping rate between steps is selectable by the capacitor size.

Ramping is much better than hard edged steps, and reduces

excitation energy that causes "singing" and resonance. With ramping,

more of the motor energy is converted to forward rotation, unlike

the "two steps forward one step back" effect of hard ringing steps.

The ramping can be tuned for main operating speed to give almost

stepless operation and very quiet and smooth rotation. Analog ramping

takes no PIC processor time and can be set VERY slow so even slow

motor speeds like 0.5 rps can be made smooth!

No other cheap stepper driver does this!

| | |

|-----| |------

| | |

| | |

| | |

----| |-----|

| | |

Normal stepper driver.

(jerky, overshoots, resonant, noisy, reduced torque)

/-\ /-\

/ \ / \

\ / \ / \

\ / \ /

\-/ \-/

With simple analog ramping.

(more "stepless", less overshoot, smoother better torque)

Here are the actual waveforms

(Shown is the DC current through the 2 motor phases. 1A = 2 vert div)

6th stepping is done in hardware

Microstepping

Uses combinations of the 3 available current levels to give 6th

stepping, or 6 times as many steps as the motor has in full-step

mode. Additional software control by the PIC gives 3600 steps!

Good for science/robot motors to move in 0.1 degree increments.

(The stepper motor itself will not position accurately down to

one 3600th of a turn, but there is still good useful positioning

and many other benefits gained from the increased smoothness.)

Microstepping has less noise, and less resonance allowing

operation to very high motor speeds. If you have only used full

step and half step drivers before you will really enjoy

microstepping. If you write custom PIC software you can get

infinite angle control by controlling the 2 motor currents with

software pwm.

Linear?

Many people don't like them, and they are definitely not

fashionable in these days of throwaway bubblejet printers with

tiny stepper chips like the UCN5804.

But, linear stepper drivers give very good MOTOR performance,

especially when you need to accelerate to high motor speeds or

need smooth "stepless" operation at very low speeds. Torque ripple

from voltage chopping is removed, also gone is the supply ripple

from chopper recirculating currents. Expensive high-speed high-

current diodes are not needed. Eddy currents and copper losses,

and recirculating diode losses are reduced and the motor gets

LESS heating with linear than with a chopper supply, although the

driver gets more. :o)

Yes this driver does get hot, and needs a heatsink!

But I designed this for my needs, ie to be adaptable to any new

motor needs I have from 200mA floppy motors that need fine

microstepping, to large 2A motors etc. I thought it was better

to have "one board does all" than to use the expensive and

tiny stepper chips.

Think "large audio amp"...

- Linear is a great way of getting an exact-shaped high freq

current into something inductive like a speaker or motor.

Current Ramping

A benefit of linear, the analog current control has an RC network,

giving a "ramp" from one current step to the next.

Ramping rate between steps is selectable by the capacitor size.

Ramping is much better than hard edged steps, and reduces

excitation energy that causes "singing" and resonance. With ramping,

more of the motor energy is converted to forward rotation, unlike

the "two steps forward one step back" effect of hard ringing steps.

The ramping can be tuned for main operating speed to give almost

stepless operation and very quiet and smooth rotation. Analog ramping

takes no PIC processor time and can be set VERY slow so even slow

motor speeds like 0.5 rps can be made smooth!

No other cheap stepper driver does this!

| | |

|-----| |------

| | |

| | |

| | |

----| |-----|

| | |

Normal stepper driver.

(jerky, overshoots, resonant, noisy, reduced torque)

/-\ /-\

/ \ / \

\ / \ / \

\ / \ /

\-/ \-/

With simple analog ramping.

(more "stepless", less overshoot, smoother better torque)

Here are the actual waveforms

(Shown is the DC current through the 2 motor phases. 1A = 2 vert div)

3 current levels, 1200 steps, no ramping (normal microstepping)

3 current levels, 1200 steps, no ramping (normal microstepping)

3 current levels, 1200 steps, with linear ramping!

3 current levels, 1200 steps, with linear ramping!

9 current levels, 3600 steps, with linear ramping!

That is a "sine-like" wave for almost stepless operation.

Operation of the constant current circuit:

Example: If voltage at point Vx is 2v (by the voltage divider),

Rsense is at (2v-1v)=1v.

If Rsense is 1 ohm the current is fixed at 1A as shown:

+12v dc

+5v ---------, |

| |

| |

,------, | Stepper

| | | coil

| | 4.5v out | |

| |------, | |

| | | | |

| PIC | R1 Rp |

| brain| | | |

| | | | C NPN Darlington

| | Vx *---*--B (1V b-e)

| | 2v | 2v E

| | | | 1v

| | ,--* |

| | | | |

| | C R2 R current

'------' | | | sense

'--* | 1v / 1ohm = 1amp

| |

| |

gnd ----------*--------*---------------

Also: A Java simulation of this circuit.

The capacitor across R2 gives the current ramping. No it's not

perfect ramping, but for a cheap simple solution it works ok.

With 6th stepping, the cap is always charged at the last level,

so when the step occurs the volts ramp smoothly to the next level.

Rp holds the transistor JUST off (at 0% current) when the PIC is

not sending an output, so any signal from the PIC will

proportionately increase the current past the zero point.

In this way the PIC sets 4 main currrent levels;

* 0% current

* 25% current

* 55% current

* 100% current

To make these levels tuneable I have provided a small prototype

area on the board where you can make resistance values by combining

two resistors in series. The resistor values I have chosen are to

give the currents above, give or take a few percent.

The hardware microstepping alone gives 1200 step operation.

In software the PIC can do modulation between any 2 of these levels,

giving "tween" current levels of any amount.

9 current levels, 3600 steps, with linear ramping!

That is a "sine-like" wave for almost stepless operation.

Operation of the constant current circuit:

Example: If voltage at point Vx is 2v (by the voltage divider),

Rsense is at (2v-1v)=1v.

If Rsense is 1 ohm the current is fixed at 1A as shown:

+12v dc

+5v ---------, |

| |

| |

,------, | Stepper

| | | coil

| | 4.5v out | |

| |------, | |

| | | | |

| PIC | R1 Rp |

| brain| | | |

| | | | C NPN Darlington

| | Vx *---*--B (1V b-e)

| | 2v | 2v E

| | | | 1v

| | ,--* |

| | | | |

| | C R2 R current

'------' | | | sense

'--* | 1v / 1ohm = 1amp

| |

| |

gnd ----------*--------*---------------

Also: A Java simulation of this circuit.

The capacitor across R2 gives the current ramping. No it's not

perfect ramping, but for a cheap simple solution it works ok.

With 6th stepping, the cap is always charged at the last level,

so when the step occurs the volts ramp smoothly to the next level.

Rp holds the transistor JUST off (at 0% current) when the PIC is

not sending an output, so any signal from the PIC will

proportionately increase the current past the zero point.

In this way the PIC sets 4 main currrent levels;

* 0% current

* 25% current

* 55% current

* 100% current

To make these levels tuneable I have provided a small prototype

area on the board where you can make resistance values by combining

two resistors in series. The resistor values I have chosen are to

give the currents above, give or take a few percent.

The hardware microstepping alone gives 1200 step operation.

In software the PIC can do modulation between any 2 of these levels,

giving "tween" current levels of any amount.