http://concreteprinter.tumblr.com/

The MassMind THB6064AH driver by Luc Degrand is a 4 Amp, 50 Volt, 200 WATT, bipolar (4, 6 or 8 wire) Stepper Motor Driver in kit form for lower cost and easy repair. 416074

Here are some samples of what you can do with it:

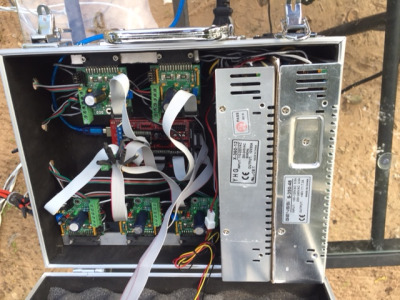

2016: Alex Le Roux and his team at VestPrint have a 3D concrete printer like

Andrey's and they are selling a kit in the USA:

(note: In 2018 Alex moved on to

https://www.iconbuild.com and is

using expensive industrial servo systems)

http://concreteprinter.tumblr.com/

2015:

Andrey

made a Monster (it over fills his two car garage)

3D printer that extrudes cement. And

that was just the model for the full sized one! He started print "tiny home"

sized buildings, but the current version prints full sized suites for resort

hotels. And what driver is running this beast? Our THB6064AH driver, of

course:

You can see it actually putting down layers at:

https://www.youtube.com/watch?v=2eNp6q35uRo

"His big printer needed big NEMA34 stepper motors, far beyond the current

capacity of the stock RAMPS stepper drivers. [Andrey] got in touch with [James]

at MassMind who helped him with an open source THB6064AH based driver. [James]

even came up with an adaptor cable and PCB which makes the new drivers a

drop-in replacement."

http://hackaday.com/2014/05/29/man-builds-concrete-3d-printer-in-his-garage/

'For a big printer, I need special drivers that can handle the heavy weight

of the machine as well as be compatible with the software/firmware. The best

fit I found was from James Newton's Mass Mind. These drivers ended up being

the only ones to work properly with Marlin Firmware (I sampled other drivers,

which failed), and were powerful enough to move such a huge printer.' Rudenko

added.

http://americankabuki.blogspot.nl/2014/09/minnesotan-man-builds-worlds-first-3d.html

Andrey's machine was last seen in the P.I. printing 2-bedroom villas for

a resort hotel there. The extruder has been upgraded (very wiz-bang now!)

and the machine is bigger now, but still running fast and smooth.

http://makezine.com/2015/09/14/3d-printed-2-bedroom-villa/

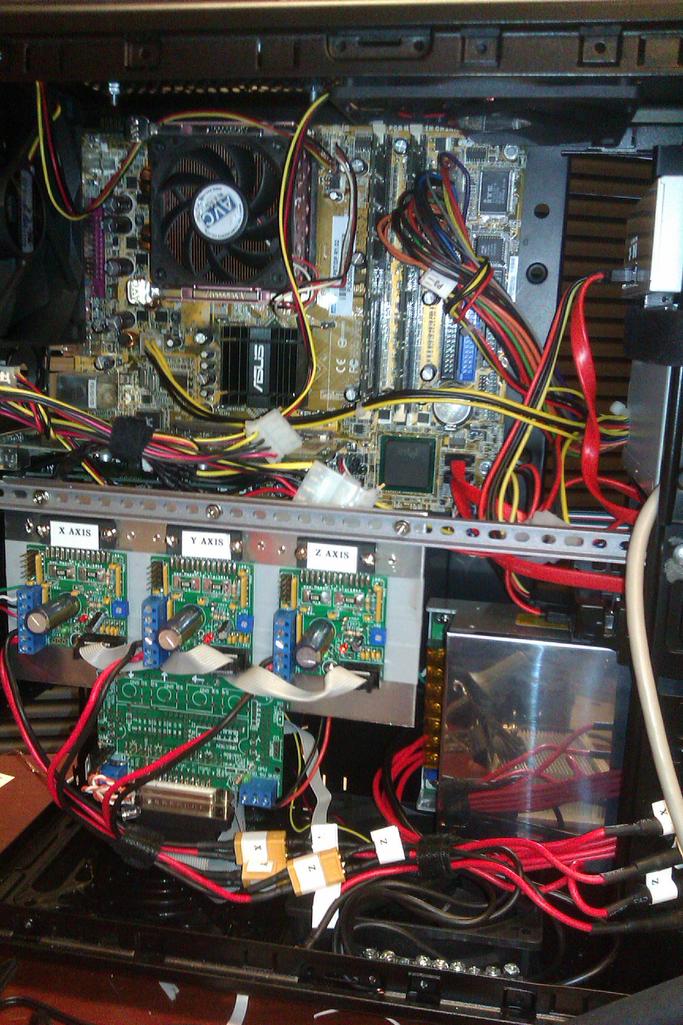

John got his Sidewinder CNC router upgraded with the MassMind THB6064AH drivers. It walks across the floor of the shop now...

Alan Redd says: "I received the kits, built them, and installed them on my lathe today. I was able to follow the instructions and get both drivers put together right on the first try. I have been using a G540, and your drivers seem to have as much power and only very slightly more noise from the steppers. I am still fiddling with the power level and the decay settings, but am very happy with the performance at the current setup."

TroyO got his Grizzly G0704 (aka BF20) running at 180 IPM with three of our THB6064AH drivers. The mechanical CNC conversion was done with ArizonaVideo's kit. The X and Y axis are Automation Technology KL23H276-30-8A 282 oz-in NEMA 23 motors and the Z axis is a KL23H2100-50-4B 570 oz-in.

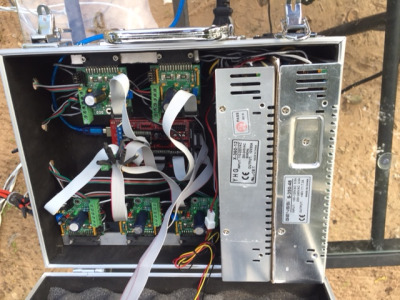

Zac Soden did a lovely job on the 'tron box for his CNC Machine! He is using his Planet CNC USB motion controller with 3 of our THB6064AH drivers.

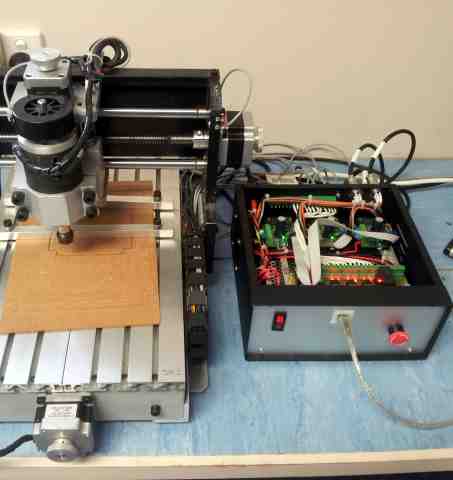

Troy converted an old PC into a CNC driver complete with THB6064AH drivers, 4Axis breakout board, Power Supply, and connections all neatly re-routed inside the case with the motherboard and hard drive.

Here are Martin Wright's 3 drivers on the heatsinks and ready to be cabled

to his RAMPs board:

Adam Baskerville^ did a lovely job mounting his three drivers. Notice the thermal paste. Those are old XBOX heatsinks.

Here is a nice video from H500 with the THB6064AH driving a Keling 280 oz-in motor (kl23h276-30-8b) on the Y Axis (in and out from the camera) at 200ipm with a 40 volt power supply and the current set to 3Amps:

And here is a comparison with the Xylotec driver. The THB6064AH provides a higher max speed with smoother stepping with the same power supply / motors / load.

See also: