|

| Parameter |

Min |

Max |

Remarks |

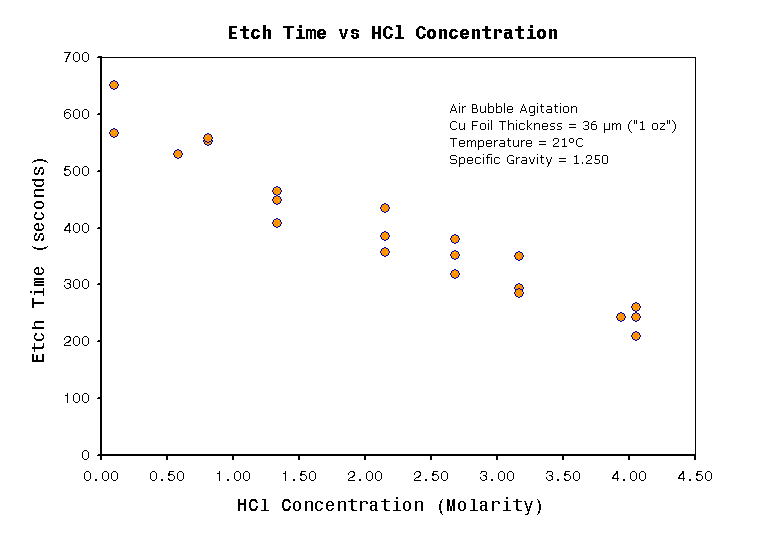

| Free acid

concentration (molarity) |

1.0 |

3.5 |

HCl fuming

increases Etch speed increases. (see note 1) |

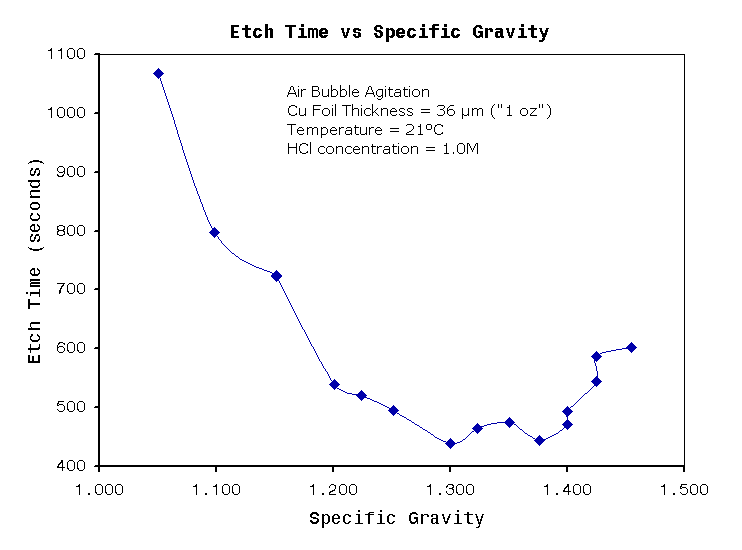

| Specific

gravity (g/cm3) |

1.220 |

1.380 |

Relatively

stable etch rate across range |

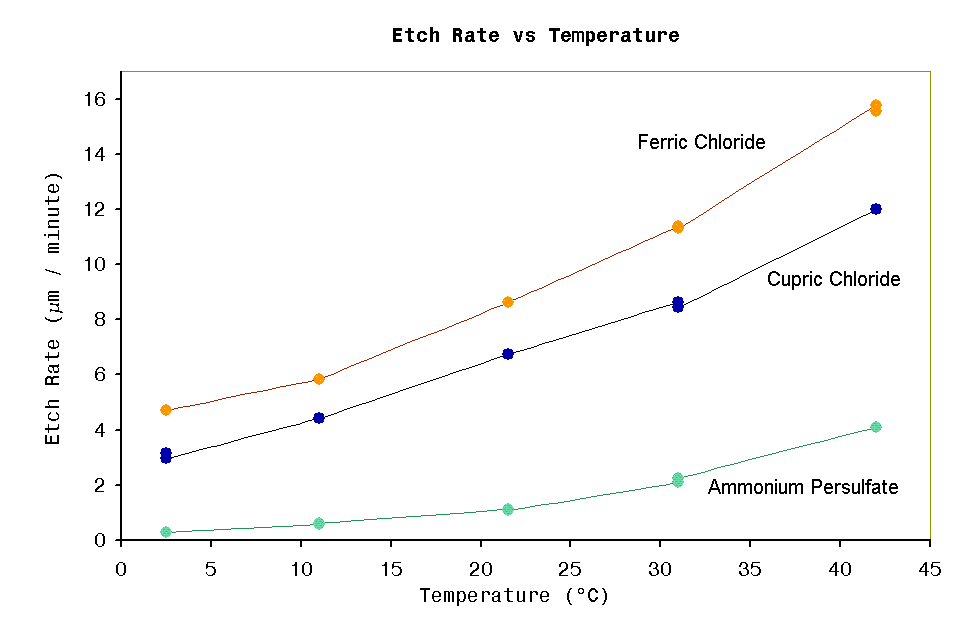

| Temperature

(°C) |

0 |

40 |

HCl fuming

increases. Etch speed increases. (see note 1) |

| Minimum bulk tank volume per board area (liters/cm2 ) |

0.016 |

- |

Assuming 50%

track coverage, double sided, 36 μm ("1oz") copper PCB. |

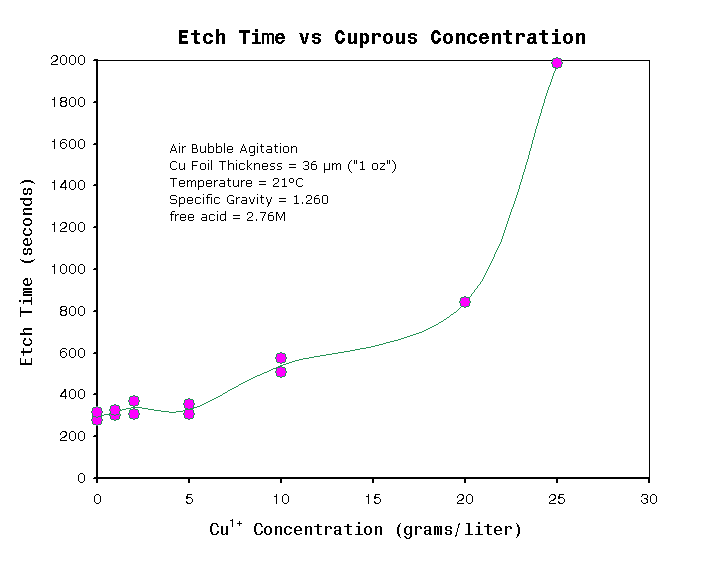

| Maximum monovalent copper ion, Cu1+ (g/liter) | - |

5 |

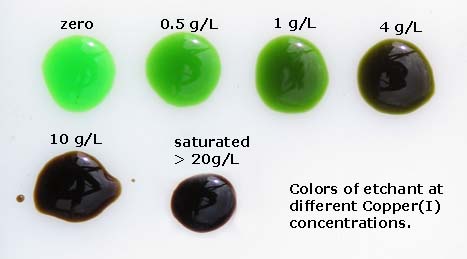

Color of

drops on white surface should appear bright green to olive dark green. Any signs of brown color indicates too high Cu1+. Also see Figure 5 |

| Method |

Chemical Ingredients | pros |

cons |

| Metal + Air |

Concentrated HCl Copper Metal Hydrogen Peroxide 3% (optional) |

Low cost Ingredients widely available |

Long time to prepare (3 to 10

days) |

| Copper(II) Oxides |

Concentrated HCl Copper Hydroxide or Copper(II) Oxide |

Quickest. Least amount of labor |

May prove difficult or costly

obtaining copper salts |

| molarity |

% weight |

grams/liter |

| 7.57 |

24.63 |

275.9 |

| 8.24 |

26.6 |

300.6 |

| 8.93 |

28.56 |

325.6 |

| 9.63 |

30.54 |

351.2 |

| 10.4 |

32.54 |

377.5 |

| 11.1 |

34.5 |

404.0 |

| 11.8 |

36.58 |

431.6 |

See also:

Questions:

Hey very nice article! thanks for that. I just have a question, is it possible to etch other alloys of copper like brass with Cupric Chloride? Thanks for your answer :-)