Break Out / Multi-Purpose Board

This page is for Version 4 of our break out board. The new version

5 is here: 4axis5build. The old version is

here: 4axis3build

4Axis Break out / Multi-Purpose PCB build instructions:

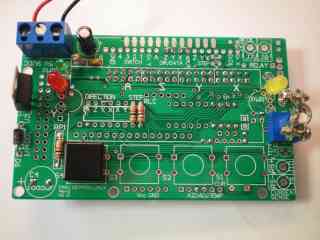

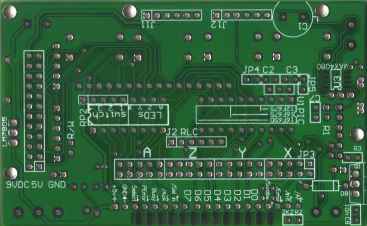

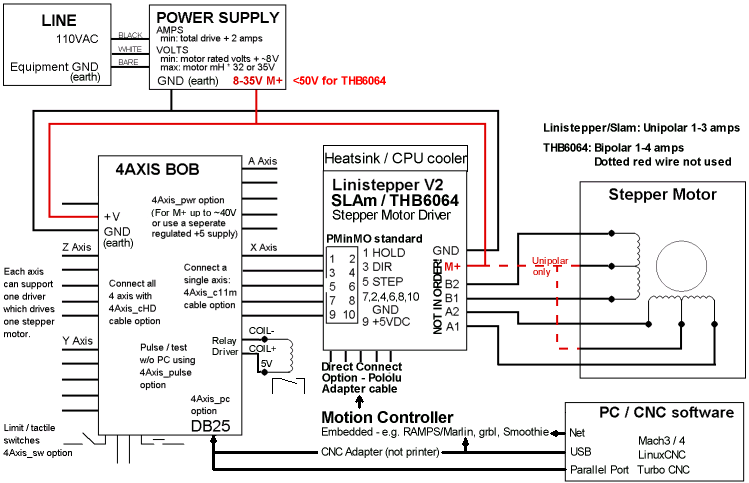

This page documents construction as a break out board for up to 4

Linistepper, SLAm

or other PMinMO^ drivers. There are many

options for this board, and not all relate to this

use. As a break out board, most users will be interested in the following

options:

|

-

DB25 connector at the top for connection to PC Parallel

port. Pin headers also support connection to white board, or use as an Arduino

"Shield" board.

-

4 Axis Header: Low cost ribbon cables (from underneath)

which terminate in standard PMinMO

plugs^ at the drivers.

-

+5 volt regulator on the left (the big capacitor is installed

underneath in this picture)

-

Pulse / Demo / Test option which replaces the PC as

the normal source of control signals with a simple variable speed STEP pulse

generator and DIRECTION control to demonstrate motor operation and test

drivers.

-

Up to 4 switches (can be limit switches or tactile switches)

and a pull up ("RP1") for them so the parallel port can be used to read

them.

-

Relay coil driver on the top right with indicator LED.

-

Space for axis step indicator LEDs, on board PIC for intelligent test and

control, serial interface, over current and temperature sensors.

|

Most people will want to use the 4Axis board to support a stepper motor driver.

Mouse over the diagram below and click on the highlighted areas to find more.

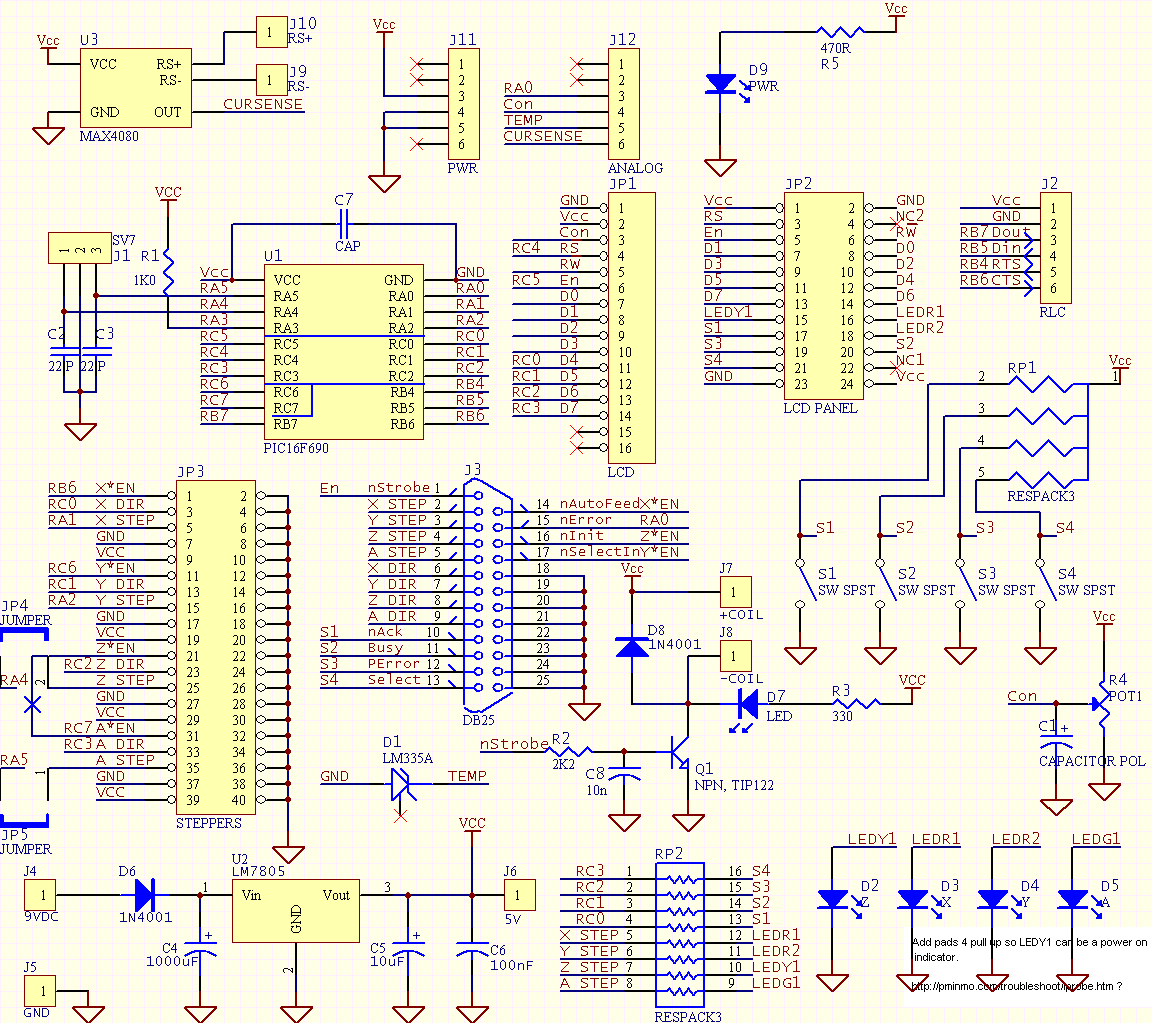

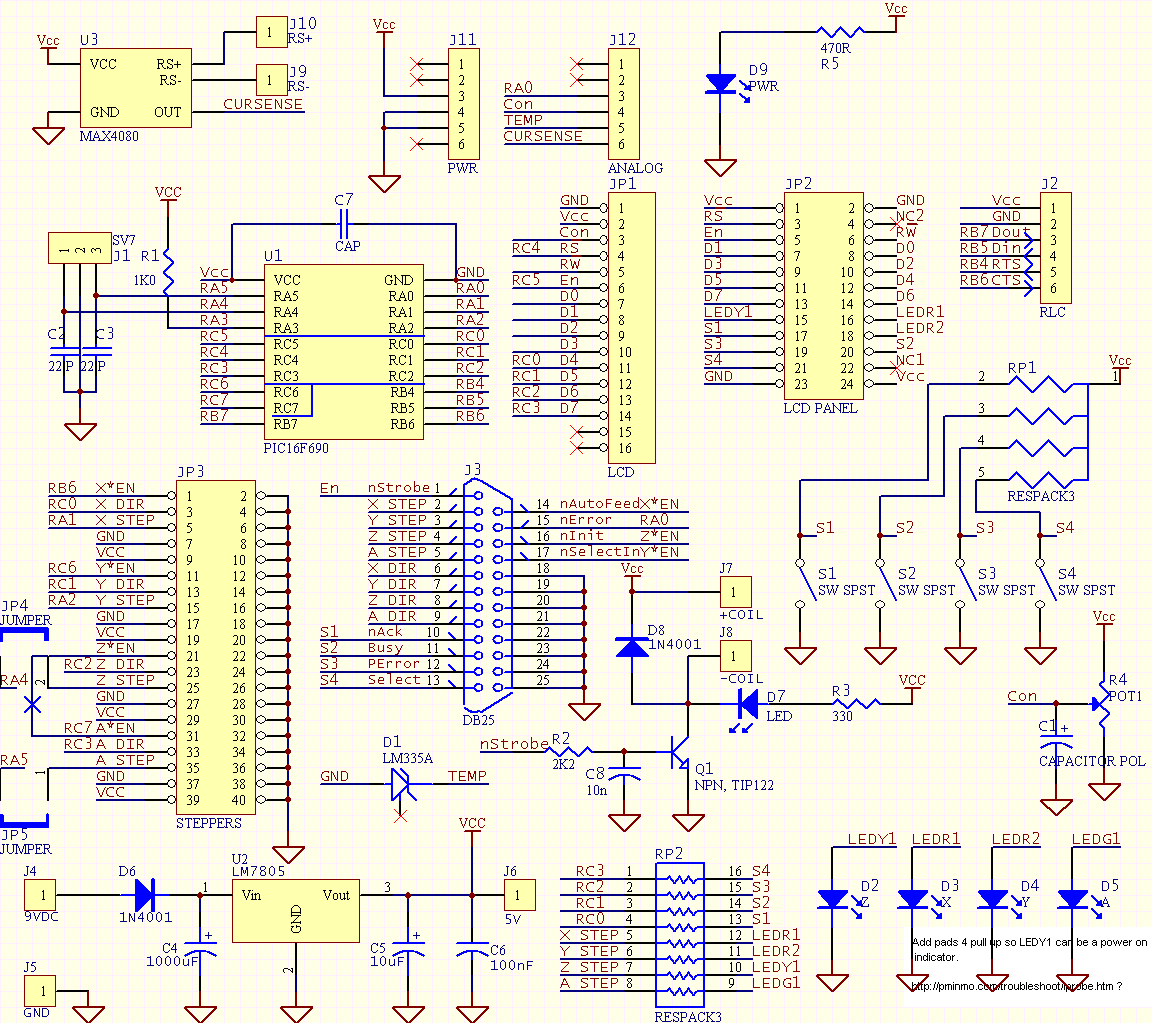

Click schematic for larger version in a new window.

There is also a google spreadsheet that shows the combination of connections

and helps clarify why they were setup as they were

^

Don't let the schematic scare you! Pretty much the entire top half are items

that will probably not be used, but were easy to work into the PCB for

future expansion, we can ignore

them for now. The only important bits are the LM7805 power regulator in the

bottom left, the STEPPERS header just above it which cables out to 4 PMinMO

driver headers (e.g. The Linistepper or

SLAm stepper drivers, and the DB25 connector

to the right of that which feeds those drivers from the PC

parallel port. The nStrobe signal

from the DB5 (see just below and right) drives a relay with LED indicator

if you like, and the RP2 resistor pack below that (right of the LM7805) and

the LED's in the lower right corner provide a visual indication of each step

(if you send a wide enough pulse from your CNC software). RP1, on the right

edge, mid way down, pulls up a set of 4 switches which can be installed on

the PCB as stop/jog switches or can be wired to limit switches or any other

connect to ground switch for feedback to the PC. Here are the instructions

for assembling each option on the board: Please note, the order of assembly

is important, as some components are difficult to reach after other components

have been soldered in.

Options: Combining all these functions

on one printed circuit board was more cost effective than making multiple

different boards, but you may not wish to populate all the parts of the board;

for example, if you run small 8 to 10 volt motors, a single ATX PC power

supply can provide both +12 volt motor supply and +5 volts for the linisteppers,

so the voltage regulator section would be redundant. To make different

configurations easy, we sell the kit(s) in separate parts:

Kit

|

Parts |

Specs |

QTY |

Description |

PCB: 416012 |

|

PCB1 |

Two Layer, plated through holes, silkscreen, soldermask |

1 |

The printed circuit board only: |

DB-25 PC Parallel Port kit: 416036 |

|

J3 |

DB25, Female, Solder tail |

1 |

DB25 pushes on to edge of PCB |

|

CBL |

DB25, Male-Male |

1 |

Cable to connect to PC Parallel Port |

Relay driver: #4Axis2RLY Not yet available.

|

| Pulse kit: 416016 |

|

U1 |

PIC12F675, DIP 8 (w/ optional socket) |

1 |

PIC Microcontroller |

|

R4 |

TRIM, 10K (w/ optional bail clamp) |

1 |

Turn the pot one way to step forward, the other to step back. Bail clamp

as handle. |

|

LEDS |

T1 |

2 |

LEDs show step and direction |

|

RP2* |

CARBON, 1/4 WATT AXIAL, 1K Ohm |

2 |

Resistors couple Step / Direction output to LEDs. Two resistors, not

a network. |

|

RP1* |

CARBON, 1/4 WATT AXIAL, 1K Ohm |

1 |

Pull up for switch. Single resistor, not a network. |

|

S4 |

TACTILE SWITCH AND COVER |

1 |

Hold to start continuous pulse, quick push for single, long push for

burst |

|

|

WIRE, ~3" |

1 |

Jumper switch to available PIC input pin. |

+5 Power kit: 416025 |

|

U2 |

LM-7805 |

1 |

5 Volt regulator |

|

J4-6 |

3 Pin, 0.2 |

1 |

Terminal Block |

|

D6 |

1N4001, 1A, AXIAL |

1 |

Reverse protection diode |

|

C4 |

ELEC, 0.2 RAD, 1000uF |

1 |

Main supply filtering |

|

C5 |

ELEC, 0.1 RAD, 10uF |

1 |

Main output filtering |

|

C6 |

CERAMIC, 0.1 RAD, 100nF |

1 |

Secondary output filtering. 22nF supplied. |

|

R5 |

1/8 WATT, 330 Ohm |

1 |

Drives indicator LED |

|

D9 |

GRN LED, 0.1 RAD, T1 |

1 |

Power indicator light |

The cable:

416014 416014

This cable is pre-wired for the PMinMO connector on the Linistepper Version

2, SLAm and other PMinMO compatible drivers. Single 40 pin 28AWG ribbon cable

with 4 IDC connectors and shrouded PCB header

|

|

General Guidelines for Assembly

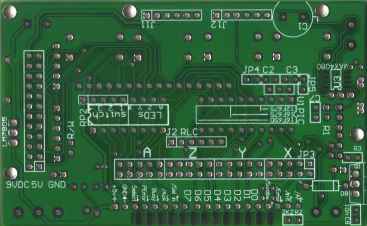

All the reference designators (e.g. R3, J1, S1) are marked on the PCB

as close to pin 1 of that part as is possible.

Pin 1 almost always has a square pad.

The assembly documentation is listed here in the order that the kits should

be assembled assuming ALL the options are being installed. Skip the sections

you don't want, but be sure to assemble in the order presented here: The

order of assembly is important as some parts can not be installed after

others.

Soldering

When soldering, use a sharp tip and as high a heat as possible. The solder

should be standard flux core and as fine as possible. Hold the solder at

the point where the lead and the pad on the board meet, then apply the (just

cleaned) iron to the other side, again, at the point were the lead and the

pad meet. Ensure there is solid contact between the solder and both metal

parts, as well as the iron tip and both metal parts. A slight grinding or

twisting motion of the iron can be helpful. As soon as the solder melts,

or in a few seconds if it doesn't, remove the iron and allow the joint to

cool as long as possible. When soldering multi-lead parts like the PIC chip,

ribbon cable header or DB25 connector, to avoid heat build up in the plastic

case, do NOT proceed in order, but rather always solder what would logically

be the coolest lead next. Stubborn points can be eased with a bit of flux

dispensed from the point of a pen or pin.

Option Assembly Instructions

| The lowest cost option for connecting the 4Axis board to your PC parallel

port is to just take an existing, good quality parallel printer cable and

cut off the printer end, then ohm out the wires to find the

Data D0-7 signals (pins 3-9 on the PC

connector) and strip/solder those wires directly into the holes labeled

D0-D7 on the bottom of the 4Axis PCB.

Of course, It's a lot quicker to solder on a DB-25 connector and use a parallel

extension cable. This connector MUST be a female connector. The cable used

from the PC parallel port should be a straight through, male to male. These

are provided in the PC parallel port kit option. The DB 25 connector is pressed

onto the edge of the PCB. It is positioned starting from the corner of the

PCB. Be sure that the pins aline with the pads (it will only align one way)

and then work one end on, and slowly rock back and forth to spread the rest

of the pins until the PCB edge is fully pressed against the plastic of the

connector. Check the pins for alignment to the pads, both top and bottom

and re-position as necessary. Also: Setup instructions for

Mach3, |

| Driver |

PC PP |

| XStep |

Pin2 D0 |

| YStep |

Pin3 D1 |

| ZStep |

Pin4 D2 |

| AStep |

Pin5 D3 |

| XDir |

Pin6 D4 |

| YDir |

Pin7 D5 |

| ZDir |

Pin8 D6 |

| ADir |

Pin9 D7 |

| Relay |

Pin1 nStrobe |

| X en |

Pin14 |

| Y en |

Pin17 |

| Z&A en |

Pin16 |

|

| |

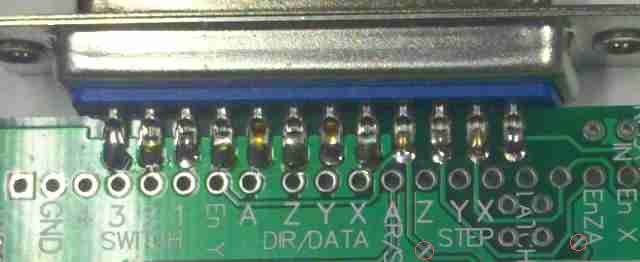

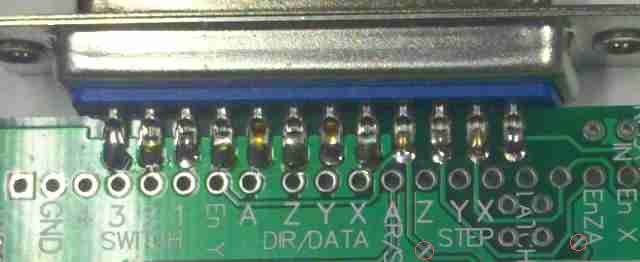

Note: This is the back of the PCB, and the row of pins under the

solder pads is marked with the signals from the DB25 as they relate to the

PC parallel port. The D pins are driving by the PC, of course, and the direction

of the other signals is indicated with a little half arrow next to the

name.

+5 and ground were added and a very slight extra space introduced between

D6 and D7 so that the holes could be used as a header for the Arduino controller.

This, along with J11 and J12 on the opposite edge of the board, allow it's

use as a "Shield" or expansion board for the Arduino. More on that below.

|

|

The next picture, below, is the back of the PCB, and the row of pins under

the solder pads is marked with the signals from the DB25 as they relate to

how they are used by the drivers and this break out board. Solder each

pin, with the iron touching the end of the pin and the pad both at the same

time, and the solder fed from the side, near the body of the connector.

| |

Note: The "En X", "En Y", and "EnZA" each connect to outputs on the

PC parallel port so that the drivers can be dropped into low power hold when

not in use. It requires a little extra setup in your CNC program, but it's

worth it for the temperature control on your motors and drivers.

| Function |

PC Parallel Port pin |

| X /EN |

14 nAutoFeed (out) |

| Y /EN |

17 nSelectIn (out) |

Z /EN

A /EN |

15 nInit (out) |

|

|

If you really don't want to use those pins, you will need to cut

the traces for the enable lines. I've added little pink circles on these

pictures to highlight the marks on the PCB showing good points to cut. There

is one in the upper photo in the lower left corner, then two in the lower

photo; one under "Z" "STEP", and the other below "EnZA". If you don't configure

the lines, make sure your drivers are getting the correct signals. The

Linistepper will pull this line low automatically, but the SLAm will put

it high (into low power) by default so you will need to ground the enable

line on the driver or here on the board.

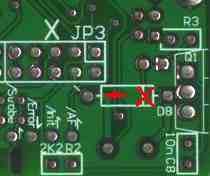

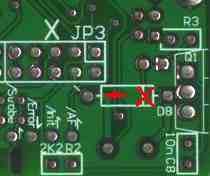

If you are going to install the relay driver, you need to do that before

you install the header for the cable that connects to each axis driver due

to a couple of slight screw ups with the reverse emf protection diode D8:

|

| |

First, the header plastic for JP3 comes right to the edge of D8's pad

and so it will melt if you solder the diode in after the header.

CRITICAL: On version 4 boards, the marking of pin 1 on the reverse protection

diode, D8, for the relay driver is backwards. This has been corrected on

version 5. Pin one is actually toward the center of the board, not toward

the edge of the board as shown on the version 4 board. Installing this diode

as marked will result in a short when the relay driver is engaged. To correctly

install the diode, on either version, place the stripe on the diode case

/away/ from the edge of the PCB (away from the drive transistor, Q1) and

towards the center of the PCB. It's best to leave the leads long enough that

the diode is about 1/2 inch in the air..

The LED installs in the little circle just under the Y in RELAY on the top;

long lead in the square hole.

The other components are pretty easy, and can be installed on the bottom

or top; pin 1, long lead, postive lead in the square hole as always.

Leave the terminal blocks for last, and as always, try to work from the center

of the board out to the edge.

|

|

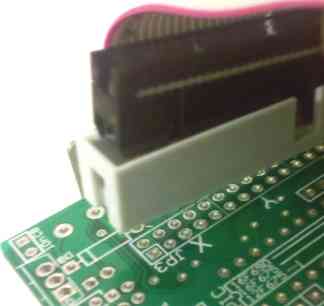

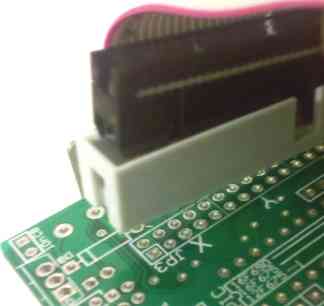

Solder the IDC header JP3 in place on the bottom

of the PCB. Pin 1 is clearly marked on the PCB, but harder to find on

the header; look for the faint "V" embossed on the side of the header shroud

pointing to pin one. The polarity notch should be opposite the DB25 connector.

The ribbon cable may not have a polarity nub to match that notch but the

red stripe should still be on the pin 1 end and there is another of those

very faint "V" symbols embossed above pin one on the connector.

Solder the IDC header JP3 in place on the bottom

of the PCB. Pin 1 is clearly marked on the PCB, but harder to find on

the header; look for the faint "V" embossed on the side of the header shroud

pointing to pin one. The polarity notch should be opposite the DB25 connector.

The ribbon cable may not have a polarity nub to match that notch but the

red stripe should still be on the pin 1 end and there is another of those

very faint "V" symbols embossed above pin one on the connector.

It turns out that not only is it very difficult to see that "V", it's

just about impossible to get a picture of it; the "V" is right there, but

totally invisible in this picture. At least the picture shows the correct

orientation

The Power kit provides regulated +5V supply for the divers internal use and

for the local options from an unregulated DC power source such as the motor

power supply.

Assembly is easy: Mount the diode, D6, first. The end with the band goes

in the square hole.

Ensure the power regulator, U2, is in as shown on the solder mask; with the

back to the outside of the PCB when inserted from the top. If you run more

than one or two axis, you may need a small heatsink. Take care not to cause

a short with solder... the holes are very close together.

Be sure to mount the capacitors with the longer lead in the hole closest

to the "+" outside the circle. The big 1000uF cap, C4, can be mounted either

on top or underneath. If you mount it on the bottom, and leave the leads

long, you can "lay it down" and secure it to the PCB with some double-back

tape or a bit of silicone. It's shown laid down on the top, just so you can

see the leads... mounting it like that could interfere with other components,

as you can see. If you want it on top, it's probably best to stand it up.

The long lead of LED D9 needs to be in the square hole toward the resistor

R5. The resistor is installed upright; with one lead straight down through

one hole and the other bent around and back down through the other hole.

Solder the terminal which replaces J4, 5 and 6 on last.

This option drives 3 of the Axis without a PC. It is designed to

demonstrate stepper motor control, and test the drivers and motors with a

known good signal. Note that this option can NOT be used with the

PC option: The board must be build as a PC interface, or a demo/test board,

not both. The step and direction signals are developed by a PIC12F675 which

is supplied pre-programmed. Because the chip has limited IO, only 3 axis

are driven, and the A STEP signal is used as the DIRECTION signal for the

other three axis.

NEW! The pulse kit has been extended to support a pushbutton switch

which will allow single stepping, bursts of steps or continuous stepping

depending on how long it is held. The kit has been updated to include a switch,

pull up resistor, and a wire to jumper the switch to an available PIC pin.

Operation: The motors turn one way or the other as you rotate the

knob of the pot. As you turn it away from center, nearer either end, the

motors will step faster and faster. Turning back from that limit toward the

other, the motors will slow, reverse, and then speed up again in the opposite

direction. One LED shows the direction of rotation, the other shows the rate

of pulses.

Assembly:

Assembly:

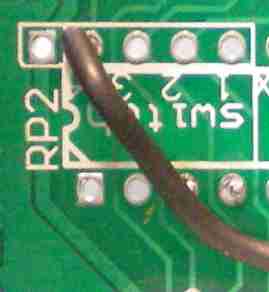

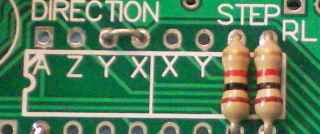

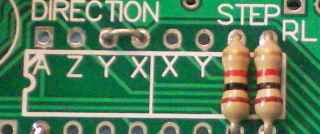

Start with two 1K ohm 1/8 watt resistors installed in the last two positions

of RP2; between A Step and the A LED, and Z STEP and the Z LED. When

you clip off the extra length on the leads, keep them! You will use

those to bridge JP4 and JP5, A STEP to all the direction lines, and two pins

of J12 (between A2D and ADJ)

Locate J12 on the bottom edge of the board. Bend on of the resistor leads

you saved in half and use it to connect pin 3 of J12 (at the "D" in the "A2D"

printed on the top of the board) to pin 4 (at the "D" in "ADJ") as shown

here:

Bend another extra lead length in half and insert it between the holes of

JP4, and solder it in place, then clip and discard the remaining length.

Repeat for JP5.

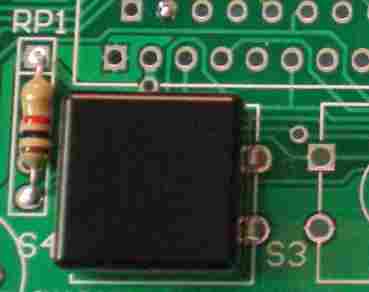

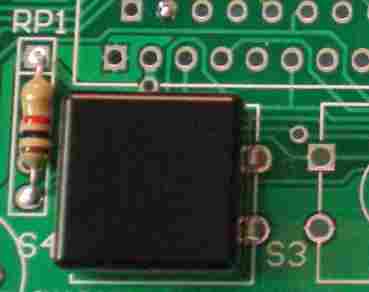

You can choose to use or ignore the IC socket. If you use the socket, you

can remove the PIC and the A STEP to XYZ DIR jumpers and still connect the

board to a PC in the future: Never both install the PIC and jumpers and

connect to a PC at the same time! Note that the PIC is installed on the

back side of PCB. Place and solder the socket or the PIC12F675 pre-programmed

chip in the highest position of U1 with the notch on the end toward "U1 PIC".

The little dimple on the top of the PIC is nearest pint 1 and should be installed

so it is in the square pad, nearest JP5 . Take care to avoid overheating

the chip; don't apply heat for more than a few seconds on each lead and solder

the leads in a cris-cross pattern, allowing time for each pin to cool before

you solder the next closest pin.

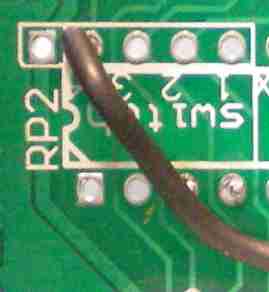

Note the end of the wire connected to the pad above R1 in the lower right

corner of this picture. On the back of the board, use the wire to jumper

RP2 pin 13 (marked as switch 1) over to R1 on the other side of the board.

That R1 pin is the one just before the "R". It is the round hole, not the

square one. Hold the board so that "R1" is right side up; the round hole

immediatly to the left of the "R". The other end of that wire goes into the

switch pin on RP2 near the other side of the board. Strip both ends, insert

and solder.

Install the ~1K ohm (BRN, BLK, RED) resistor between pin 1 and pin 5 of RP2

(normally a network resistor, but since we are only using one switch, supplying

a single resistor allows us to keep the cost of the kit down), and install

the switch in the S4 position.

Install the LED's which will show direction and step signal. When you

clip off the extra length on the leads, keep them! You will use those

to bridge the X, Y and Z DIRECTION signals to the A STEP signal, as described

a little later on.

The LEDs can be installed in two different positions depending on the type

of display you like: If the direction LED (installed on the "A" step indicator

near the pot) is installed between the square pad (long lead) and the next

pad towards the pot, it will light when the motors are going forward, and

go out when they turn reverse. In the picture below, the LED on the

right is being inserted in that way; long lead in the square hole, short

lead pointed to the hole it will fill. If you install it in the pads with

the silkscreened circle and the little picture of an LED, it will do the

opposite. In either case, the long lead must be in the hole furthest from

the pot. The STEP LED is installed on the opposite end of the board, in the

"Z" step indicator near U2. If you install it with the long lead in the square

hole, the LED will be out most of the time, and flash briefly with each step

pulse. If installed in the circle, it will be one most of the time, and blink

out briefly with each pulse. In the picture below, the red LED on the left

side is being installed in this manner. Again, the long lead must be in the

hole farthest "up" the board.

The potentiometer goes on top of the schematic symbol of a variable resistor

on the right side of the board, viewed from the top. See the picture above.

Because the shaft can be a little hard to turn, we include a "bail lock"

which can be screwed onto the shaft for a better grip. Hold the two brackets

"spooned" with a clearance hole adjacent a threaded hole and start both screws.

Slip the bail lock over the white shaft of the pot and tighten the screws.

Using the excess leads from the LED's you saved above, jumper the A STEP

to X DIR and Y DIR to Z DIR at the top front of the PCB then jumper X DIR

to Y DIR just left of the resistors as shown below. If you would like one

motor to always turn forward, you can leave out a jumper. Leave these sticking

up a bit so you can clip them if you decide to connect to a PC in the future.

Don't connect the board to a PC parallel port while these jumpers are

installed, that would short the port pins together and might burn out the

port.

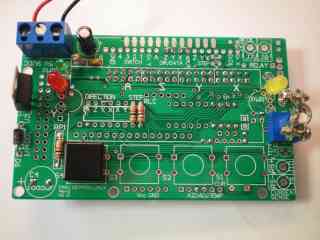

Once the pulse parts are installed, you can apply +5 volts via the holes

in the upper left corner of the board or by installing the +5

regulator option. The LED's should blink, then begin to operate. When

connected to drivers (probably by the Header/4 Axis

cable), the motors should begin to turn as you move the pot. When the

potentiometer is perfectly centered, it will not pulse at all, so if you

don't see a light, turn it left a bit and try again. Right of center, the

direction will be low and it will step faster and faster as you reach the

limit. Left of center will step in the opposite direction, again, faster

as you reach the limit. Pushing the button once should stop the pulsing,

then each quick push should step once. Push a bit longer for a burst of pulses

and hold the button until the light stays on, then release it to re-start

continuous pulsing. Here is a picture of the finished pulse / demo / test

unit with the +5 regulator option in operation:

Although a kit is not yet availble, you can add limit switches by installing

RP1, a 1K to 5K ohm, SIP resistor network (bussed, not isolated) with 5 or

more pins. Jameco part 267910 is fine. The pin with the dot goes in the square

pad, and if there are more than 5 pin, cut off the extras or just snap the

resistor as shown in the picture. The little blue 2 pin headers (Jameco 152347)

are optional if you can solder your wire directly into the pads, but they

really make it easy for larger wires like the standard ZIP cord used here.

Almost any micro switch will work, as long as you can solder your wires to

the switch terminals. Here is each switch and the parallel port pin it connects

to.

| Switch |

Parall Port |

Pin |

|

The switches act by grounding the pin, while RP1 tries to pull

the pin up to +5 volts. The direct connection of the switch can always overpower

the resistor, so the result is ground when the switch contacts meet and +5

when they are open. |

| S1 |

nAck |

10 |

|

| S2 |

Busy |

11 |

|

| S3 |

PError |

12 |

|

| S4 |

Select |

13 |

|

Eratta:

The marking of pin 1 on the reverse protection diode, D8, for the relay driver

is backwards. Pin one is actually toward the center of the board, not toward

the edge of the board as shown. Installing this diode as marked will result

in a short when the relay driver is engaged. To correctly install the diode,

place the stripe on the diode case /away/ from the edge of the PCB (away

from the drive transistor, Q1) and towards the center of the PCB.

Questions:

416014

416014

Solder the IDC header JP3 in place on the bottom

of the PCB. Pin 1 is clearly marked on the PCB, but harder to find on

the header; look for the faint "V" embossed on the side of the header shroud

pointing to pin one. The polarity notch should be opposite the DB25 connector.

The ribbon cable may not have a polarity nub to match that notch but the

red stripe should still be on the pin 1 end and there is another of those

very faint "V" symbols embossed above pin one on the connector.

Solder the IDC header JP3 in place on the bottom

of the PCB. Pin 1 is clearly marked on the PCB, but harder to find on

the header; look for the faint "V" embossed on the side of the header shroud

pointing to pin one. The polarity notch should be opposite the DB25 connector.

The ribbon cable may not have a polarity nub to match that notch but the

red stripe should still be on the pin 1 end and there is another of those

very faint "V" symbols embossed above pin one on the connector.

Assembly:

Assembly: