Point of making for Ultra High Accuracy Digital Clock (Ver2)

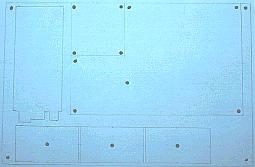

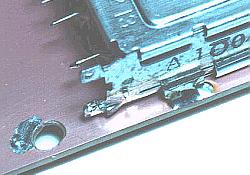

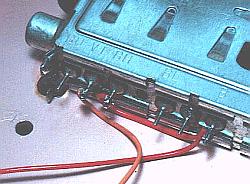

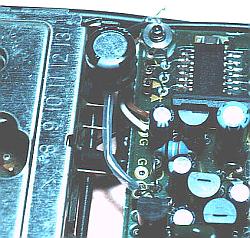

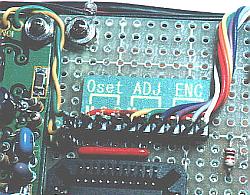

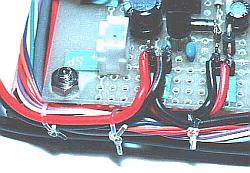

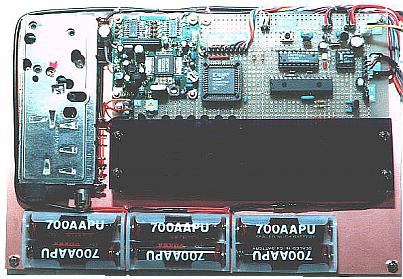

A clock main unit, a PLL oscillator, a TV tuner, backup batteries are mounted on the printed board. I used paper to decide the position of the holes to mount these units. It mounts these units onto the paper and it marks the position of the mounting holes. Holes can be made in the right position if using this paper. A clock main unit, a PLL oscillator, a TV tuner, backup batteries are mounted on the printed board. I used paper to decide the position of the holes to mount these units. It mounts these units onto the paper and it marks the position of the mounting holes. Holes can be made in the right position if using this paper. After making holes, it paints a flux to the printed board for preventing from rust. To make a printed board clean before painting a flux is needed. Also, after painting a flux, it pays attention so as not to touch with the hand. The work with the glove is good.  A TV tuner is soldered to the printed board. A TV tuner is soldered to the printed board.As for the soldering iron, the solder doesn't melt successfully when one with big thermal capacity isn't used. I used the 80W soldering iron. It solders about four and it fixes a tuner on the printed board tightly. The sure electric connection is important. It solders to the mounting part of the PLL oscillator, too.It is to improve an electric connection. Because a flux is painted to the printed board, there is possibility that the electric contact becomes bad. It applies solder thin. After applying solder, it removes extra solder by the desoldering wire and so on.  In the interval of the mounting of a TV tuner and a PLL oscillator, it is narrow. So, wiring for the TV tuner is done before putting a PLL oscillator. In the interval of the mounting of a TV tuner and a PLL oscillator, it is narrow. So, wiring for the TV tuner is done before putting a PLL oscillator.  After mounting a PLL oscillator, a coupling capacitor is connected between the picture input terminals of the PLL oscillator and the picture output terminal of the TV tuner. A 1 mm thick Teflon tube is covered to the lead wire of the capacitor to prevent touch with the other circuit. The vinyl tube can be used, too. Because the vinyl tube is weak about the heat, it needs quick soldering.  It wires in the terminal. It wires in the terminal.In the place where there is many wiring, it ties with the vinyl string.   The completion of the main unit part. |