|

There's more than a difference in appearance separating fluorescent and incandescent lamps. An incandescent bulb generates light through heat. When electrical current passes through the tungsten filament, it heats to the point where it glows and gives off a yellow-red light. To keep the filament from burning up immediately, it's housed in a vacuum. Even so, the intense heat of the filament ensures a comparatively short and expensive life span.

A fluorescent lamp has no filament running through it. Instead, cathodes (coiled tungsten filaments coated with an electron-emitting substance) at each end send current through mercury vapors sealed in the tube. Ultraviolet radiation is produced as electrons from the cathodes knock mercury electrons out of their natural orbit. Some of the displaced electrons settle back into orbit, throwing off the excess energy absorbed in the collision. Almost all of this energy is in the form of ultraviolet radiation.

To turn this radiation into visible light, the inside of the tube has a phosphor lining. The phosphors have the unique ability to lengthen UV wavelengths to a visible portion of the spectrum. Put another way, the phosphors are excited to fluorescence by bursts of UV energy.

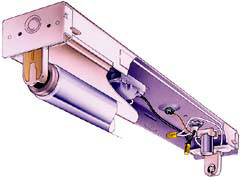

The easiest fluorescent fixture to explain is a design offered by Sylvania in 1938. This early preheat model is no longer made, but millions are still in service, and its principle design features are found in every new fixture.

|

The heart of every fluorescent fixture is its ballast. The ballast consists of a wire winding on an iron core, which reduces and regulates the voltage that flows through it. Electrical current enters the fixture through the ballast. From there, it flows through wiring to lamp holders, and ultimately, to cathodes within the tube.

However, more power is required to start a fluorescent lamp than to maintain it. Preheat fixtures get their name from a starting circuit that sends increased current through the cathodes to heat their coated filaments. The heated cathodes send a high-voltage pulse along the tube that creates an arc through the mercury vapor. As the atmosphere inside the tube heats up, electron activity increases to its most efficient, ballast-sustained level, and the mercury vapor carries the current on its own. The starting circuit is controlled by a starter switch that opens after a short preheat period (see preheat starter circuit diagram).

A variation of the starter-switch concept can be found in small desk lamps. Here, however, the starter switch is manual you simply hold down the switch button until enough heat is generated to sustain the arc through the mercury vapor.

Beyond the starter mechanism and a little fine-tuning, subsequent fluorescent fixtures have changed very little. Both the Instant-Start (1944) and the Rapid-Start (1952) versions are merely adjustments to improve reliability and reduce maintenance.

Instant-Start fixtures have ballasts with continuous output high enough to strike an arc instantly. Because no preheating occurs, Instant-Start tubes need only one pin at each end. While some Instant-Start tubes have bi-pin bases, the pins are joined at the base. In this case, they're merely structural and not electrical (see Instant-Start circuit diagram).

Modern Rapid-Start fixtures are also designed without starters, though they are true bi-pin/preheat fixtures. They have smaller, more efficient ballasts with built-in heating windings that preheat the cathodes for quick starts (see Rapid-Start circuit diagram).

Fluorescent tubes have several real advantages over incandescent lamps. They are a good deal more efficient, producing more light per watt of input than incandescents. While a standard incandescent bulb might last 1000 hours, a fluorescent lamp might last 9000, with 6000 to 7500 hours being average. In fact, the number of hours that a tube operates has less of an effect on tube life than the number of starts it endures.

The greatest hesitation that most of us have about fluorescents is the ghoulish-green light given off by cool-white lamps. Warmer, more flattering lamps have been around for years, but they generally produce less light, and are more expensive to operate.

Recent advances have solved the color-versus-efficiency quandary. New rare-earth phosphors, applied in layers, now put warm-tone lighting in the high-efficiency category. You'll easily pay three to four times more for the tubes than for cool whites, but you'll also use less energy.

The previous data was copied from Popular Mechanics magazine as "saving for posterity" attempt. I use to find out that good information at Internet just disappear without leaving traces... so I save here what is good.