6

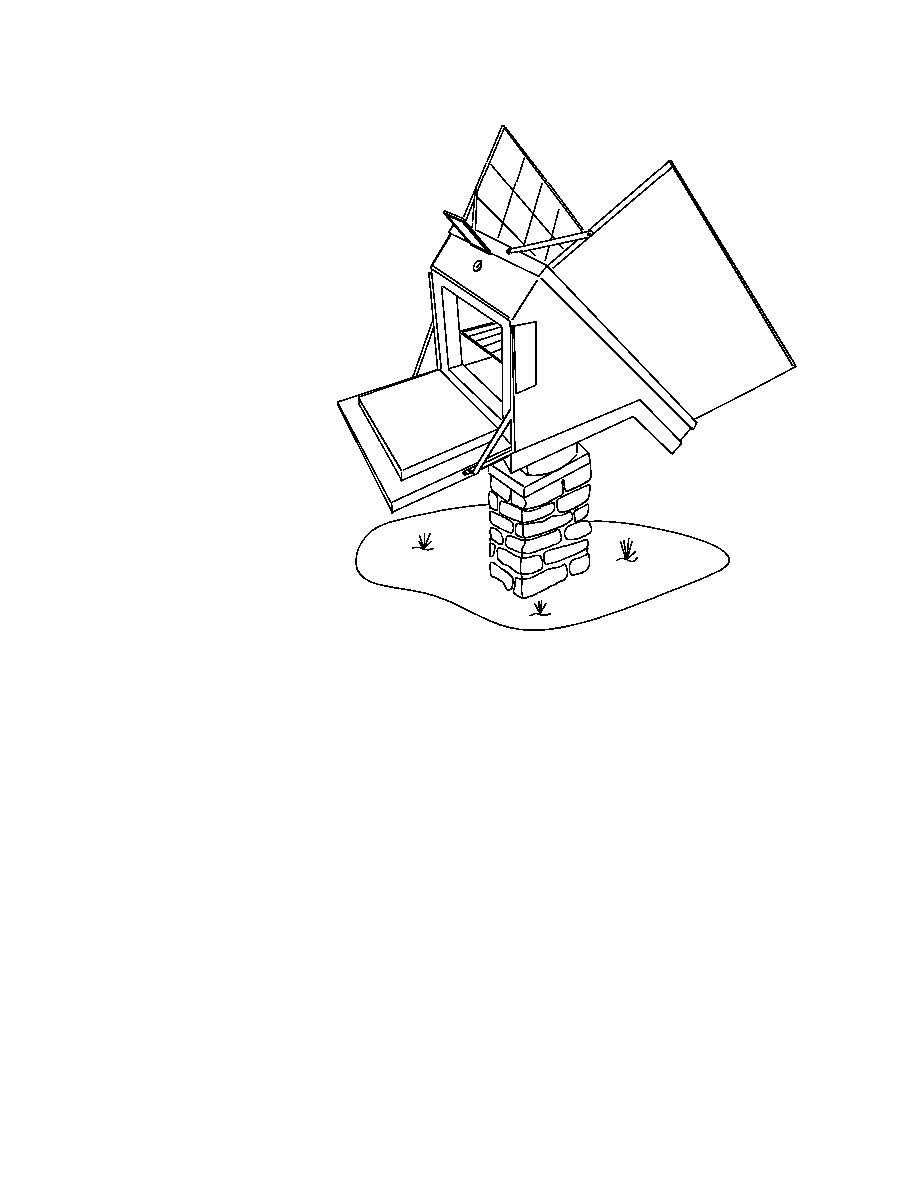

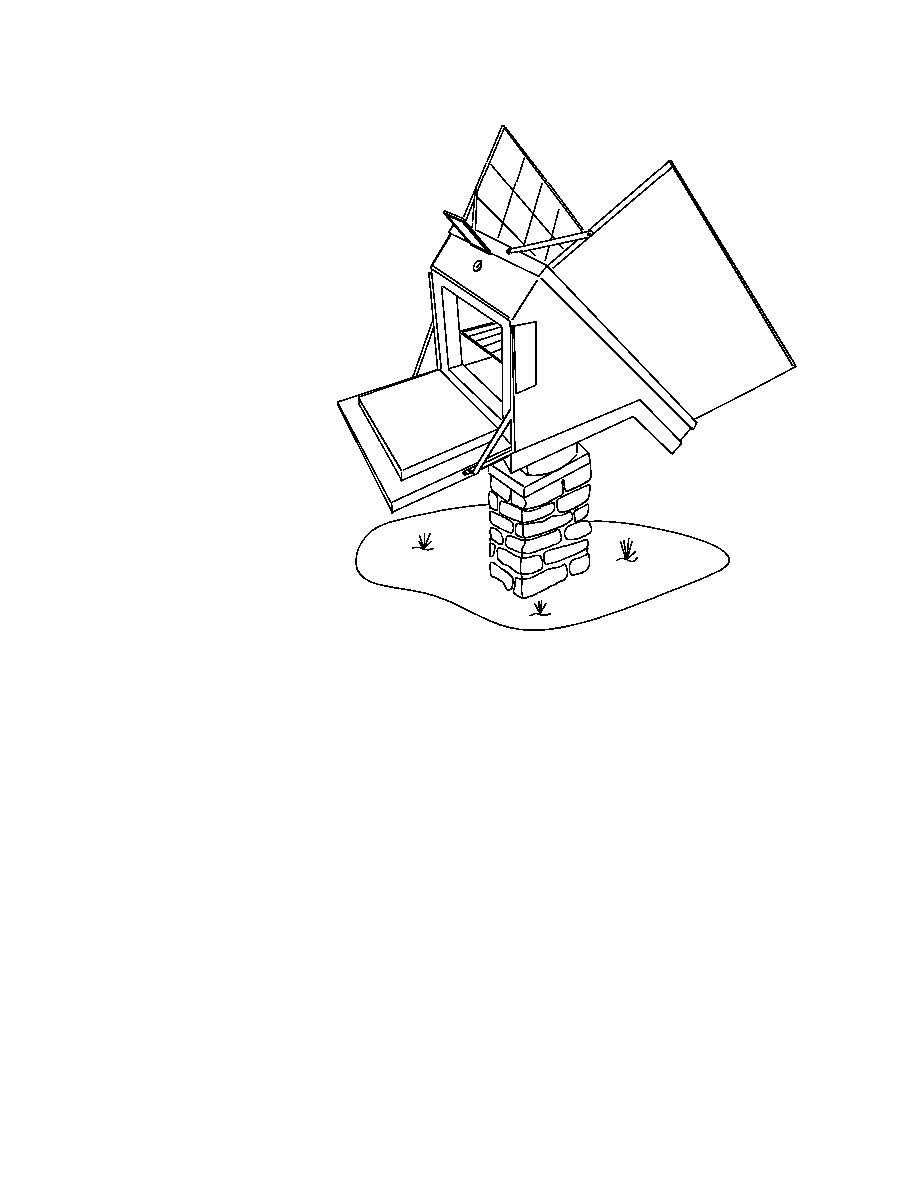

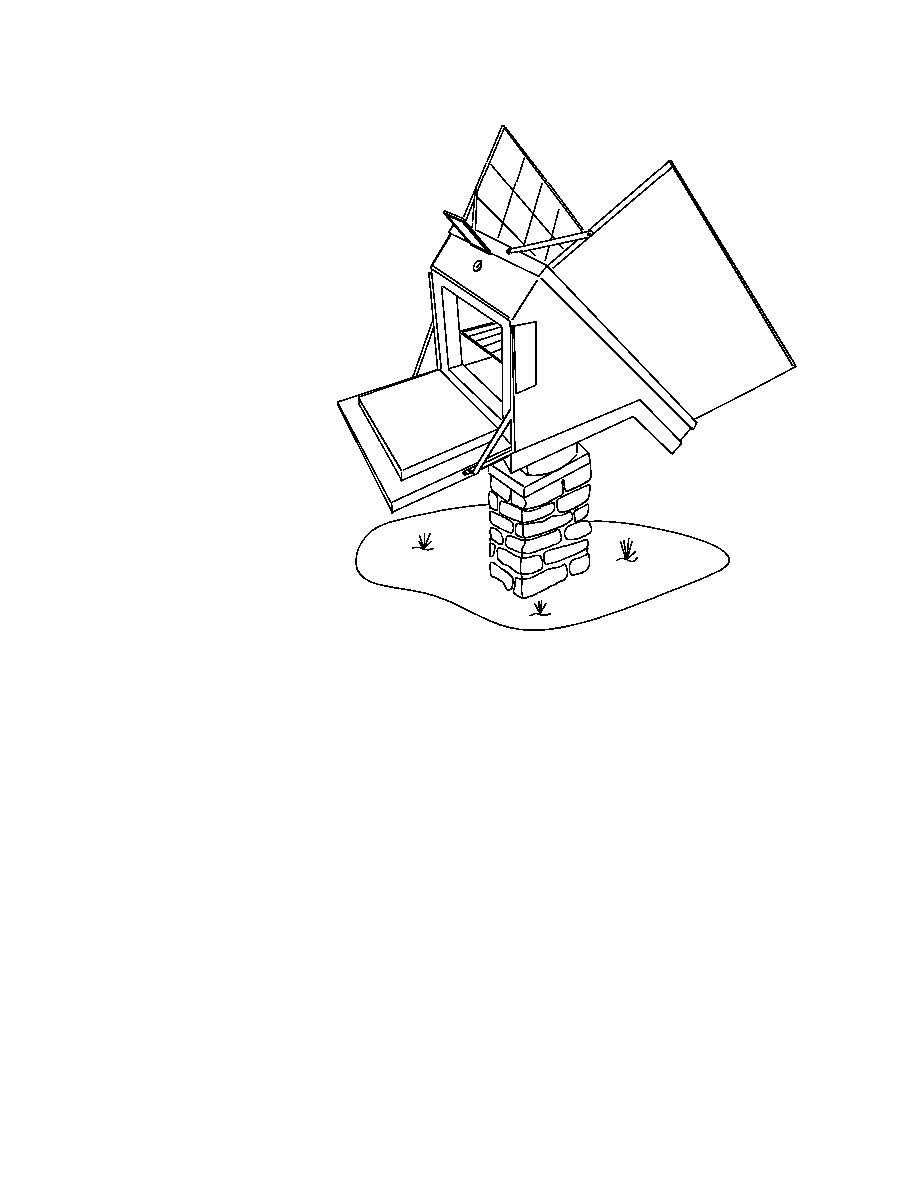

SHELL CONSTRUCTION

There are many

different ways to build an

insulated box or shell. My

first oven used foil covered

1 inch Duct Board used in

the air conditioning trade.

Using a sharp knife and a

flat iron you can form up

the shell in any size you

want using commercial

heat seal tape. Set the

angle of the face at about

your latitude plus ten

degrees measured from the

horizon (42 degrees in

Tucson) for the best

average performance all

year. When the shell is

complete another layer of

Duct Board is used to form

a liner. This will yield a

total of two inches of

insulation, with foil on both sides.

Sheet metal trim can be used to finish the shell, but most of the metal used consists of small sheets of

scrap metal. After the openings and corners are trimmed the large areas of the sides are left unprotected.

The duct board has been exposed to the weather for eight years without harm (except for the

woodpeckers); however, it is best to cover the sides completely with metal.

The door is sheet metal, one inch thick encasing duct board and two inches thick at the opening. A

leveling compound of silicone gasket paste was used to form a flat face gasket that is nearly air tight.

The door is attached with a piano hinge and a counter-weight, such that the door forms a shelf when

opened against fixed stops.