THE TRACKING SOLAR COOKER

Copyright 1987, 1988, 1990, 1992, 1993 by

C. Alan Nichols P.E., C.E.M.

Tucson, Arizona

All rights reserved

1

INTRODUCTION

The concept of solar cooking began over 220 years ago and was used

by the French Foreign Legion starting in the 1870's. All solar cookers work on

the principle of concentrating the direct solar rays to raise food or water to

cooking temperatures. Cooking temperatures begin at about 150 degrees F.

although temperatures of 250 to 400 degrees F. are preferred.

Open reflector type solar cookers focus the sun's rays on open cooking

pots or pans. Solar ovens trap the sun's heat inside insulated boxes with transparent lids. Most solar

ovens are variations of the bread box type developed by two Arizona women, Barbara Kerr and Sherry

Cole.

These simple box cookers created in the 1970's are now being used world

wide to overcome food shortages in developing countries. In places like Eastern

Africa native women travel 20 to 30 miles to gather a two day supply of cooking

fuel. In other parts of the world increasingly high rates of malnutrition are caused

by a lack of fuel. Basic grain foods cannot be cooked without cooking fuel and

water infected with chronic bacteria must be heated before drinking. Continued gathering of wood

cooking fuel by chopping down trees has resulted in eroded hill sides with loss of precious topsoil thus

reducing their ability to grow food.

In America we concern ourselves with such things as

operating costs, air pollution, acid rain and the green house

effect. Let's say it takes one hour to cook a pot of beans on an

electric stove using one kilowatt. The coal fired power plant

that supplied the electricity consumed one pound of coal and

released 17.5 cubic feet or two pounds of CO2. The power plant also consumed 0.7 gallons of ground

water and released traces of SO2 as acid.

Suppose you are cooking outside. Five pounds of steaks on a grill will use a ten pound bag of

charcoal and five ounces of lighter fluid. This fire will produce approximately 160 cubic feet or fifteen

pounds of CO2 and untold air pollution. Wood fires are even worse.

Cooking in the home averages over 100 hours a year consuming approximately 1,175 kilowatt

hours. At a cost of $0.10 a kilowatt hour this amounts to $117 a year. During the summer cooking adds

$50 to the air conditioning bill bringing the total to $167 a year. In Arizona, solar cooking can replace

70% of the cost of cooking. This will save 1,675 pounds of coal and 3,000 pounds of CO2 generation

from coal fired electric utilities.

Clearly solar cooking has come of age.

2

HOW SOLAR OVENS WORK

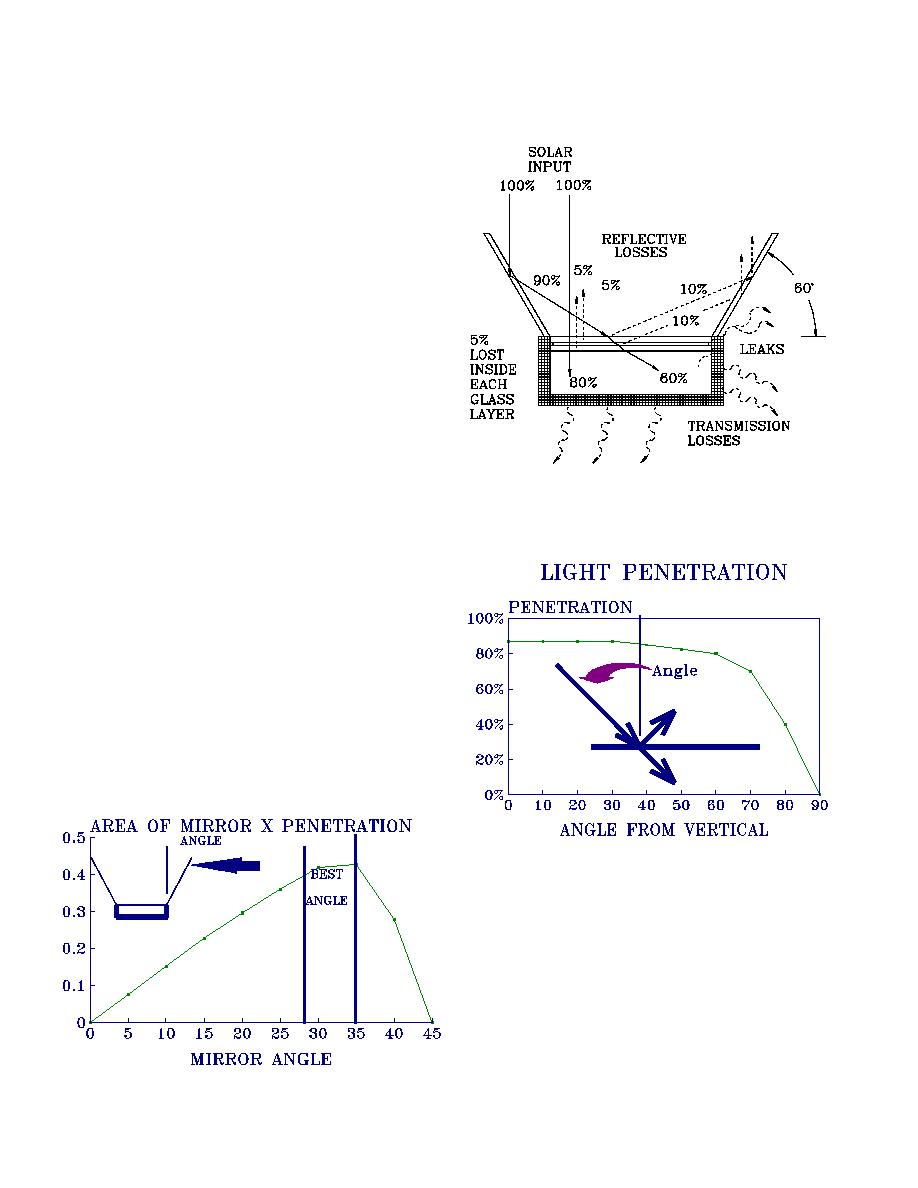

A solar oven's cooking temperature is

reached when the solar gain equals the heat

losses. Thus an oven's cooking temperature is a

balance between solar gain and heat losses.

Heat losses fall into five categories:

1. Reflective losses

2. Absorption Losses

3. Transmitted Losses

4. Leakage Losses

5. Food losses (Heat Lost To Cooking)

Solar gain is a factor of the total area

exposed to the sun and the effectiveness of

collection.

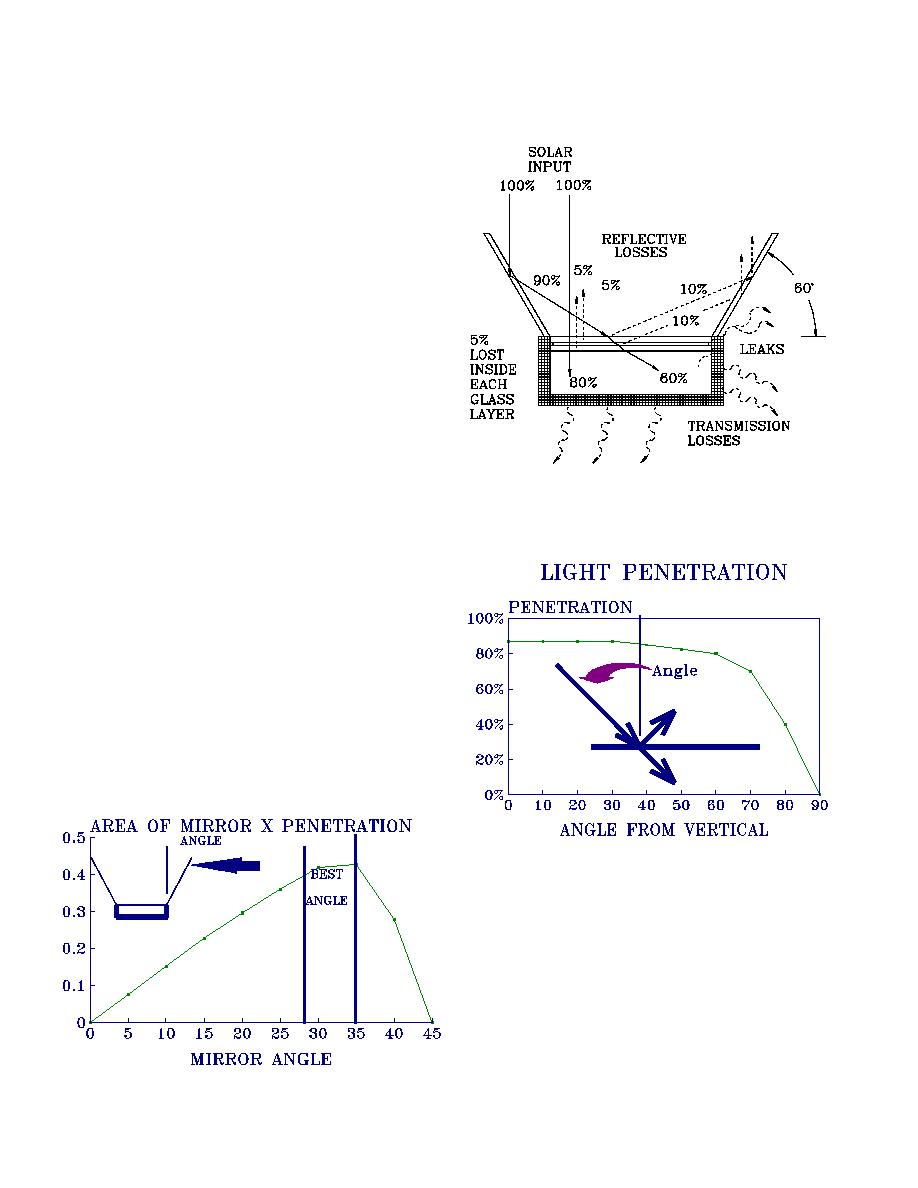

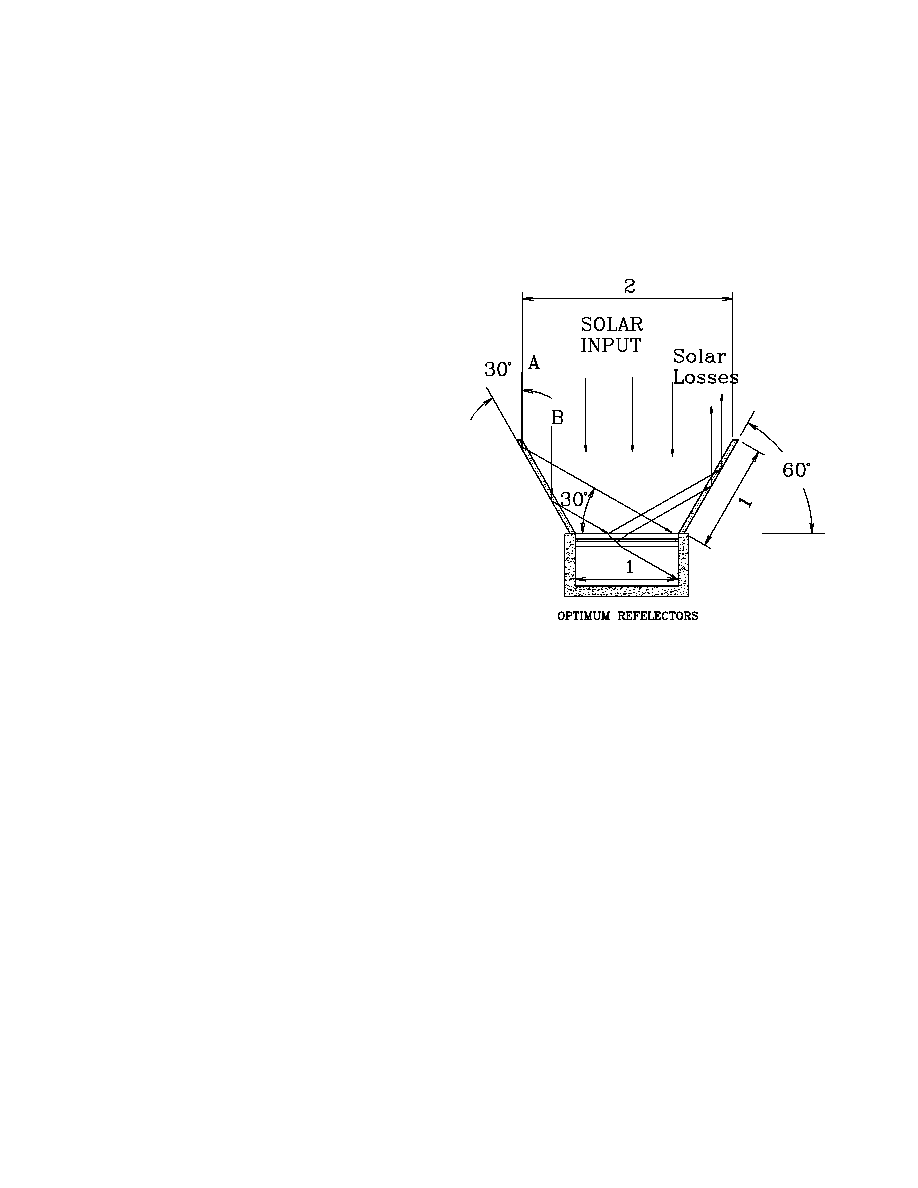

For the reflectors this property is

acceptable but for the cover glass, light must enter

the cooking chamber, or the mirrors are of no use. As a stone skipping across water, sunlight will skip

off the surface of glass without penetrating if the angle is too shallow.

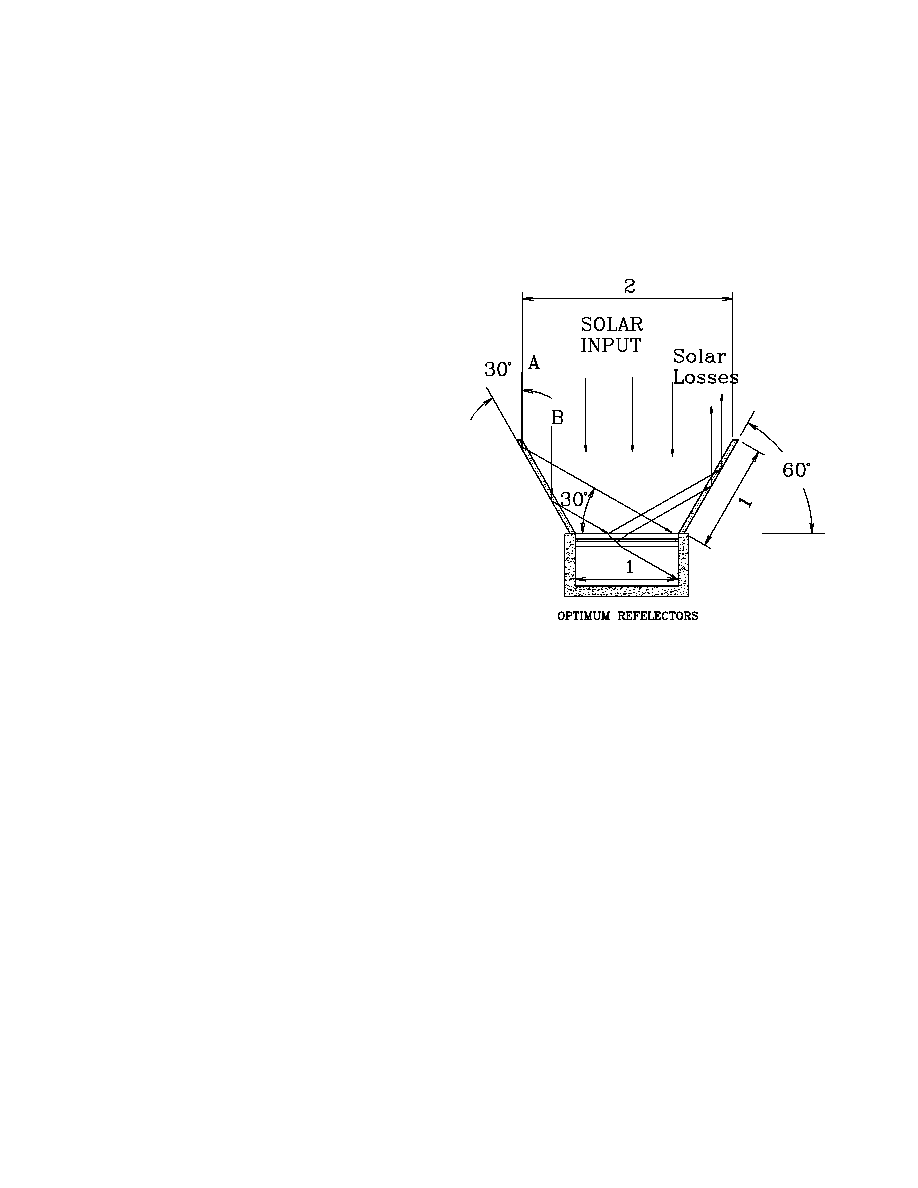

An angle of about 30 degrees from the

vertical for the mirrors or reflectors yield good

penetration with a healthy spread for an optimum

use of materials. As it turns out a reflector equal

to the width of the cooking chamber produces an

optimum design for use of materials.

With such a fortunate set of circumstance

the reflectors can be folded to cover the cooking

chamber making the cooker portable!

Mirrors have a reflection of about 99% but lose

5% each time the light passes through the glass.

Polished metal surfaces have about 90% reflection but

no losses due to glass. The result is that each behaves

about the same.

Light striking the far edge of the reflector

should enter the cooking chamber at the far edge

opposite the reflector to be beneficial. An angle of 30

3

degrees from the vertical (or 60 degrees from the horizontal) with each reflector equal to the width of the

cooking chamber will allow all the light striking the reflectors to enter the cooking chamber. With this

geometry you can still fold the mirrors!

An optimum sized cooker will cook just about anything you put in it. Extending the reflectors to

make the collector larger will produce more heat and will cook food faster.

If you extend the

reflectors the cooker becomes less portable. Doubling the length of the reflectors increases its width by

only 20% because the angle must be steeper. The shallow sun angle on the reflectors makes them more

reflective. The penetration into the cover glass improves somewhat because of the more vertical angle.

Of the five factors affecting a cooker's

cooking temperature three of them were thermal

loss. Transmitted losses are controlled with

insulation. Double glass covers have twice as

much insulation value as single glass covers.

Leakage losses are controlled with good tight

construction. The chamber should be well fitted

and protected from moisture on the inside.

Solar heat is transferred into the food by

three mechanisms. First by direct solar rays, that

is sunlight striking the food directly. This is

somewhat like a broiler. Second by convection,

that is by the hot air surrounding the food inside

the chamber. Third by conduction of heat from

the tray upon which the food rests. If the tray is a

heavy metal conductor such as steel or aluminum the sun's rays will heat the tray and conduct the heat

under the food like a stove. All three mechanisms combine to make the food cooking process very

efficient.

Finally, as the sun's energy is transferred into the food the thermal loss drops the oven's

temperature 25 to 50 degrees initially. This loss is only temporary.

As the food approaches the oven's temperature the aroma begins to fill the air, that's the whole

idea behind solar cooking.

4

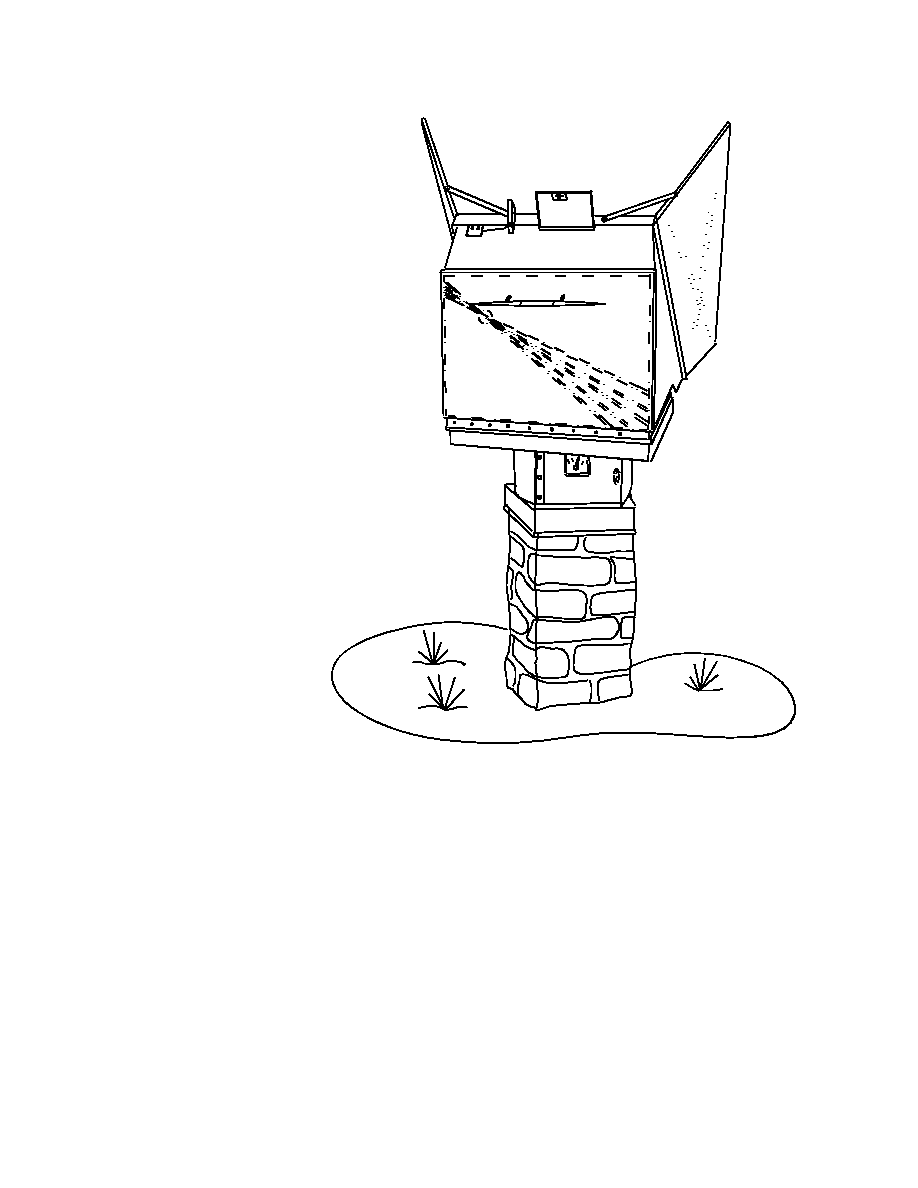

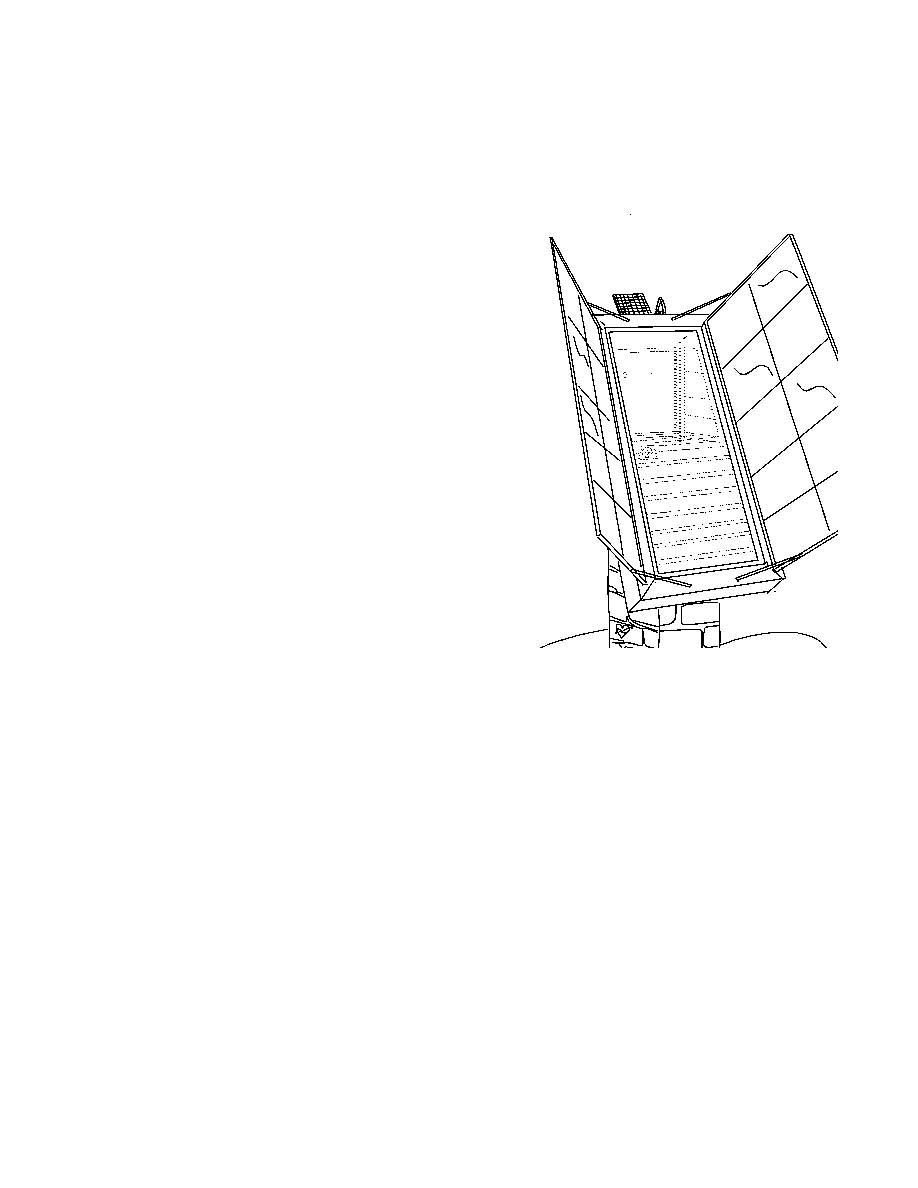

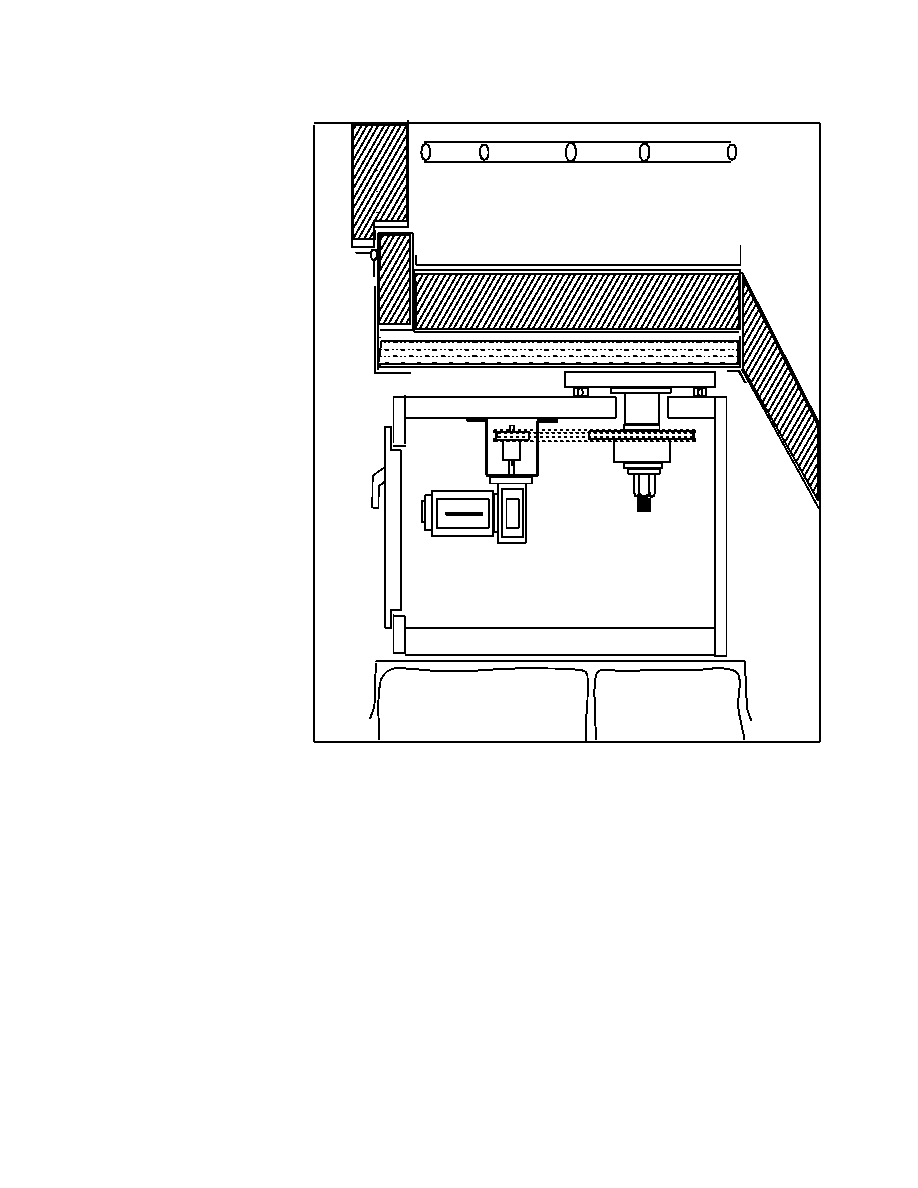

INTRODUCTION TO THE TRACKING SOLAR OVEN

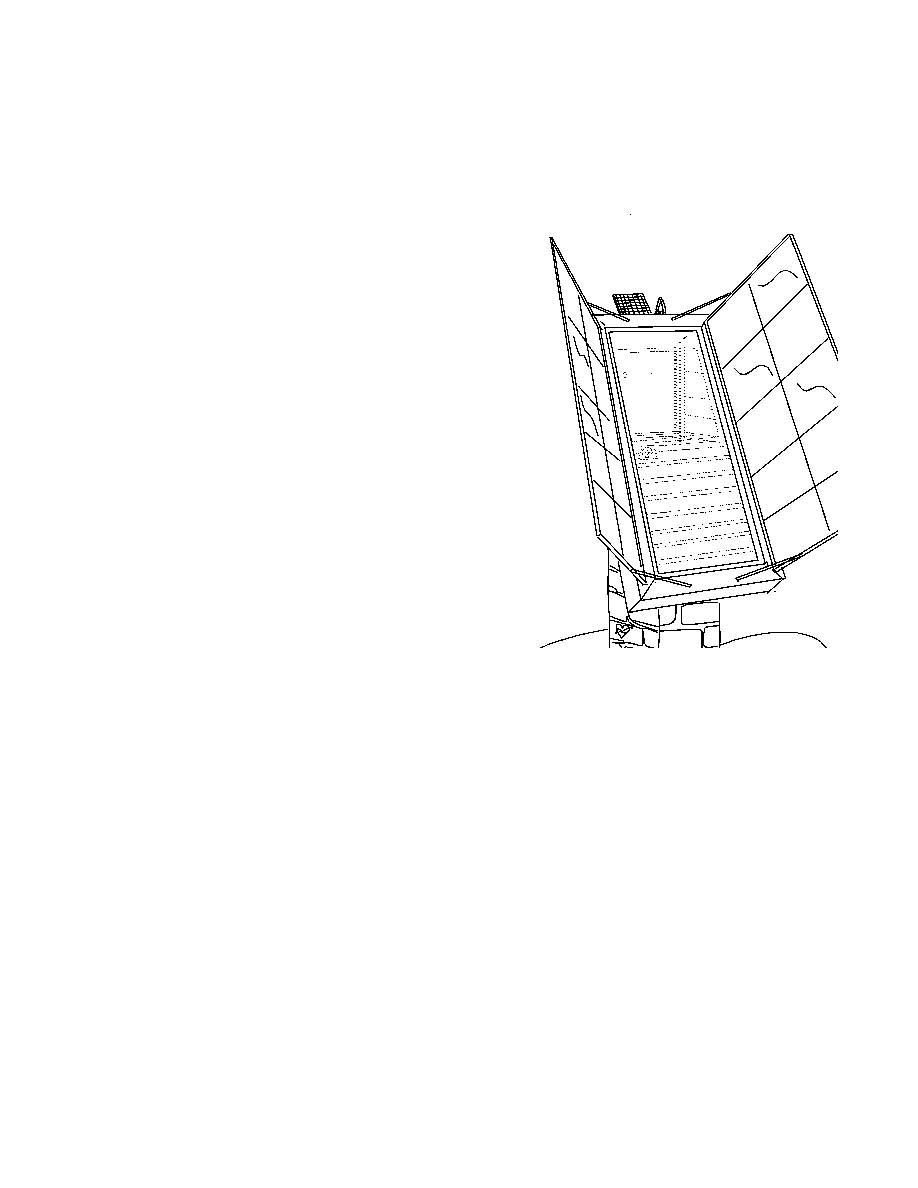

This modified box cooker has been labeled

high tech, because of its ability to follow the sun

under its own power. The design described here

is not that of a portable oven. Materials used are

durable and meant for many years of outdoors

use.

The main features are:

- Pedestal mounted where the oven is at

counter height.

- Fixed tilt such that the collector does not

have to be adjusted for the time of year.

- Uses both mirrors and flat plate collector

to concentrate the sun's heat into the

cooking chamber.

- Natural air movement increases

convection cooking and warms the

cooking tray.

- Rotation about a fixed vertical axis

allows tracking of the sun during the day

by manual or automatic means.

- Capable of heavy food load.

Energy saving is best achieved when the solar device is used to its fullest extent, thus the design

of this oven is targeted for widespread use by those who demand convenience. This design requires no

attention during the day when cooking a large meal.

These instructions will provide a basic summery of the construction techniques for building a tracking

cooker of your own. There are many construction techniques that will produce the same results.

5

HOW THE OVEN WORKS

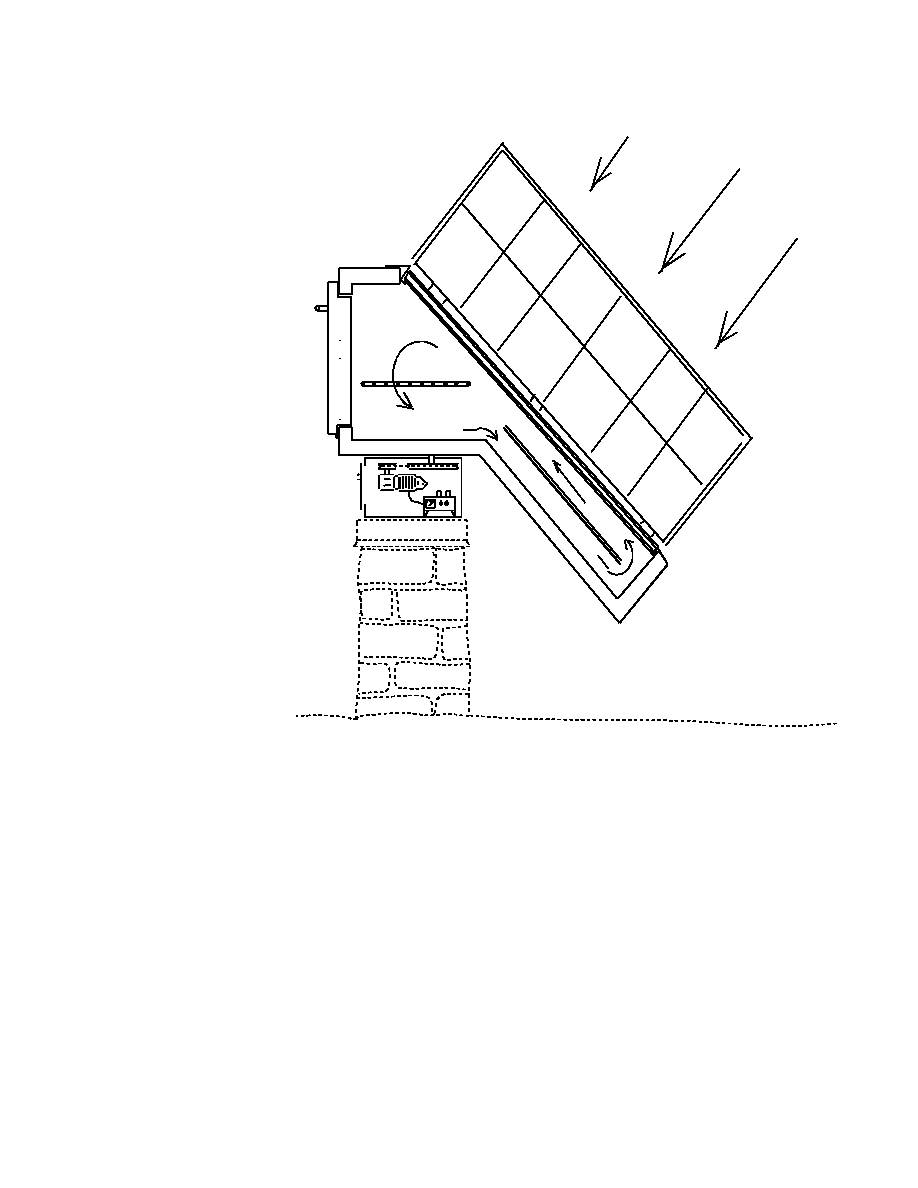

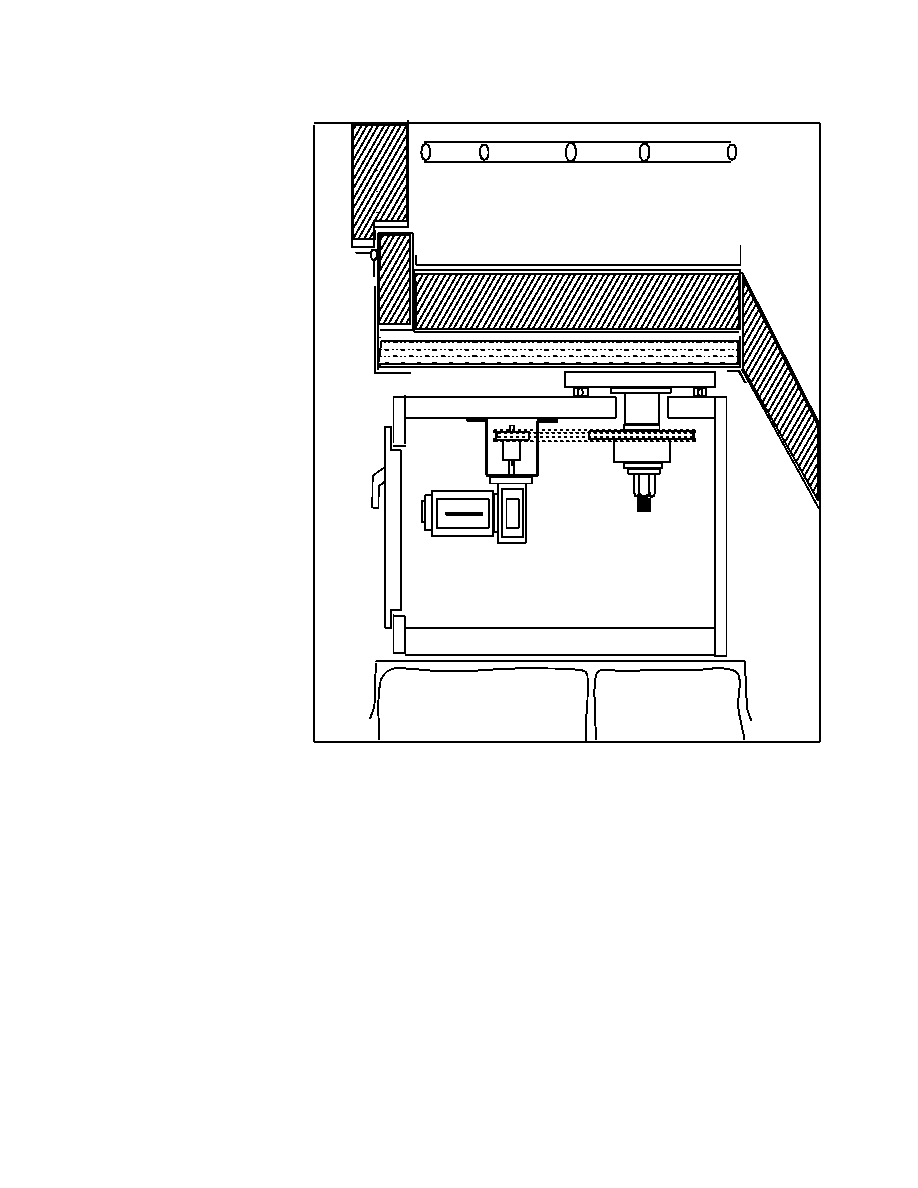

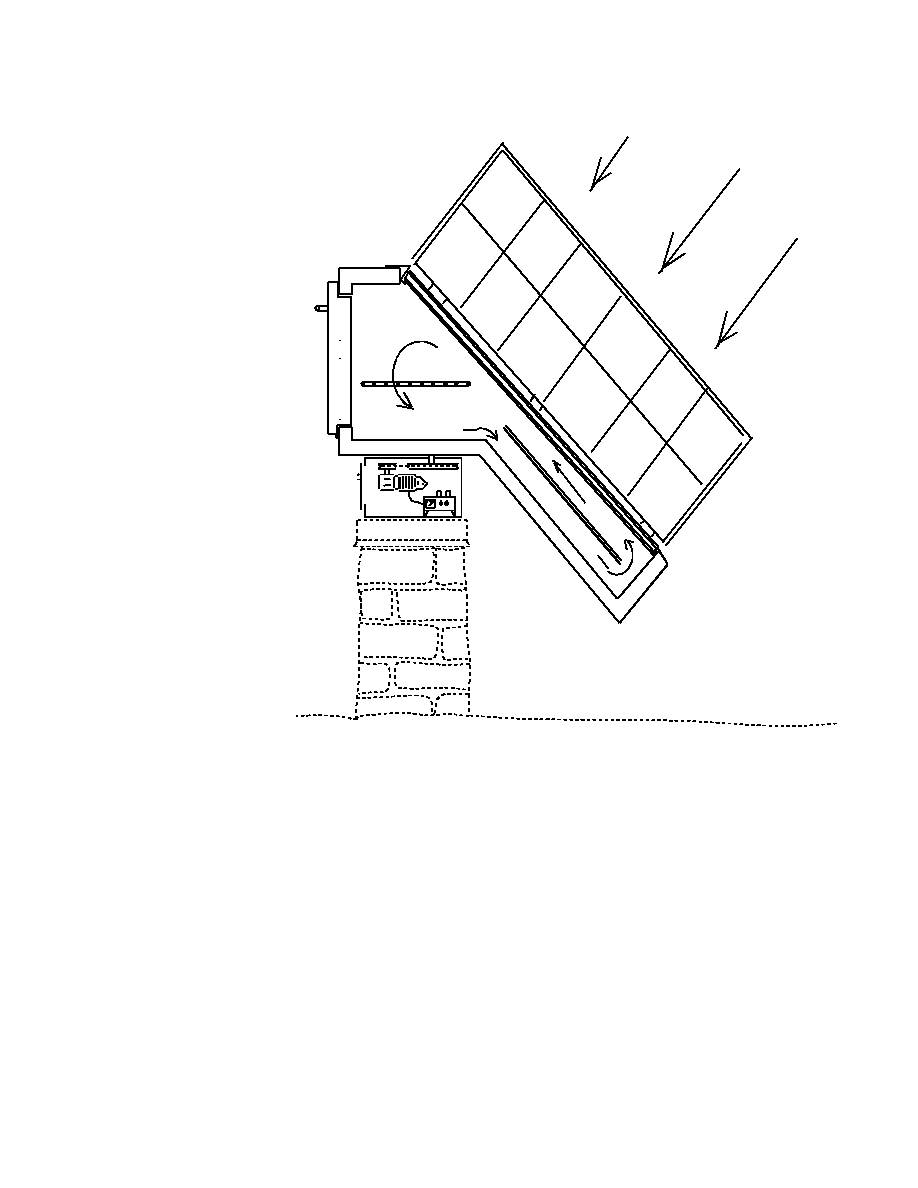

As with all solar

cookers, mirrors intensify

the sun's rays into a glass

covered, insulated box with

a door for placing and

removing food. This oven

uses a built in flat plate

collector to collect heat on

the bottom to increase

efficiency. The flat plate is

very efficient and therefore

reduces the over-all size

yet providing a larger

cooking chamber. The

high temperatures required

for cooking require the use

of mirrors.

The diagram shows the

hot air circulation pattern

within the oven and

cooking chamber. The

mirrors may fold for easy

transportation of the

cooker.

The oven mount is a

fixed pedestal with a Lazy

Susan bearing. This allows the cooker to track the sun all day long. The tracking mechanism uses a very

small amount of electrical energy making it possible to operate the oven on small batteries and a photo

cell charger.

The oven door is at counter top height and is a standard oven size. These features make cooking with

the sun as familiar and easy as cooking in your own kitchen.

6

SHELL CONSTRUCTION

There are many

different ways to build an

insulated box or shell. My

first oven used foil covered

1 inch Duct Board used in

the air conditioning trade.

Using a sharp knife and a

flat iron you can form up

the shell in any size you

want using commercial

heat seal tape. Set the

angle of the face at about

your latitude plus ten

degrees measured from the

horizon (42 degrees in

Tucson) for the best

average performance all

year. When the shell is

complete another layer of

Duct Board is used to form

a liner. This will yield a

total of two inches of

insulation, with foil on both sides.

Sheet metal trim can be used to finish the shell, but most of the metal used consists of small sheets of

scrap metal. After the openings and corners are trimmed the large areas of the sides are left unprotected.

The duct board has been exposed to the weather for eight years without harm (except for the

woodpeckers); however, it is best to cover the sides completely with metal.

The door is sheet metal, one inch thick encasing duct board and two inches thick at the opening. A

leveling compound of silicone gasket paste was used to form a flat face gasket that is nearly air tight.

The door is attached with a piano hinge and a counter-weight, such that the door forms a shelf when

opened against fixed stops.

7

GLASS ASSEMBLY

The insulated glass

panel is easy to make from

ordinary window glass and

glass spacers. Have the

glass store cut half-inch

strips of quarter-inch plate

glass and two sheets of

single weight glass slightly

smaller than your opening.

Use the glass strips and

silicone adhesive to form

two layers of single weight

glass separated by a frame

of quarter-inch glass

spacers around the outer

edge. This forms an air

space between the two

glass sheets. A drain or

vent hole to prevent

pressure buildup inside the

air space is required. The

glass panel can now be

sealed into the opening

making the oven rain-tight.

Recently I added a third

glass layer to make a triple-

insulated cover that increased the cooking temperature 25 degrees F.

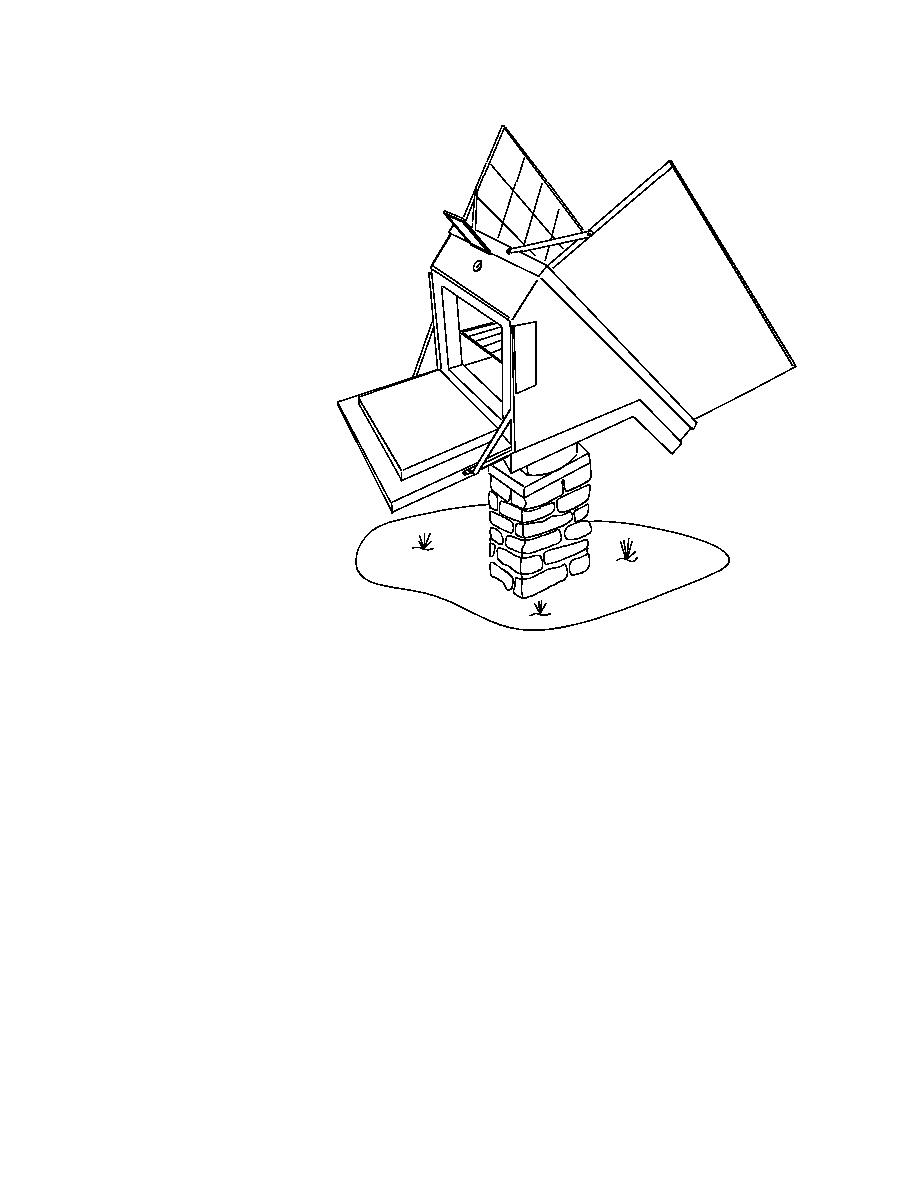

The mirrors should be the twelve inches plain edge type mirror tiles glued onto two overlapping flat

pans. Mirror tiles have the thinnest glass and make the best reflectors. The mirror pair will then nest

together when closed. The mirrors must be mounted at sixty degrees from the opening for best

performance. Knee hinges from an old folding table have work very well to hold open the mirrors and

later to fold up when needed.

8

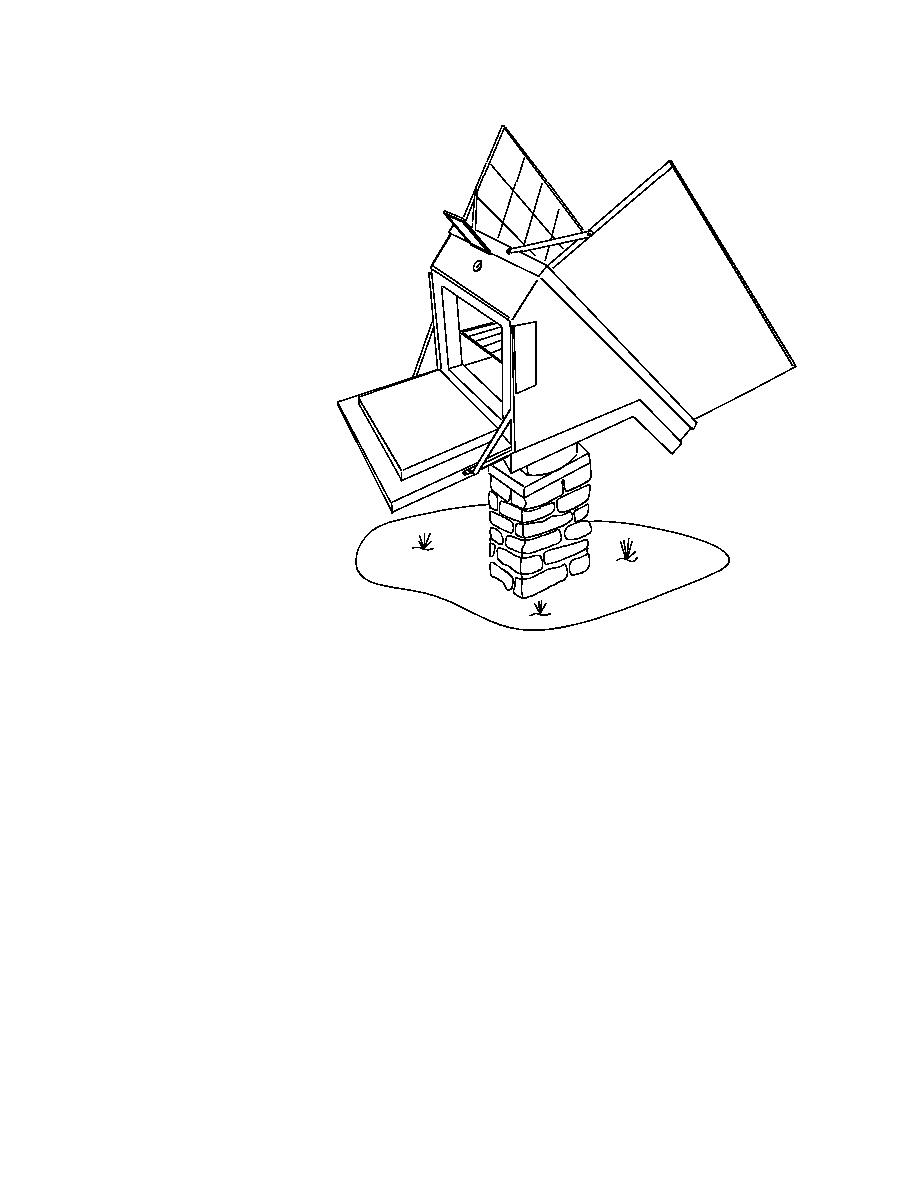

BASE CONSTRUCTION

The base should be

cylindrical shaped with a

flat side for the door.

Since the oven is supported

by the base, the material

used should be strong

enough not only to hold the

weight of the oven but

support it during high

winds as well.

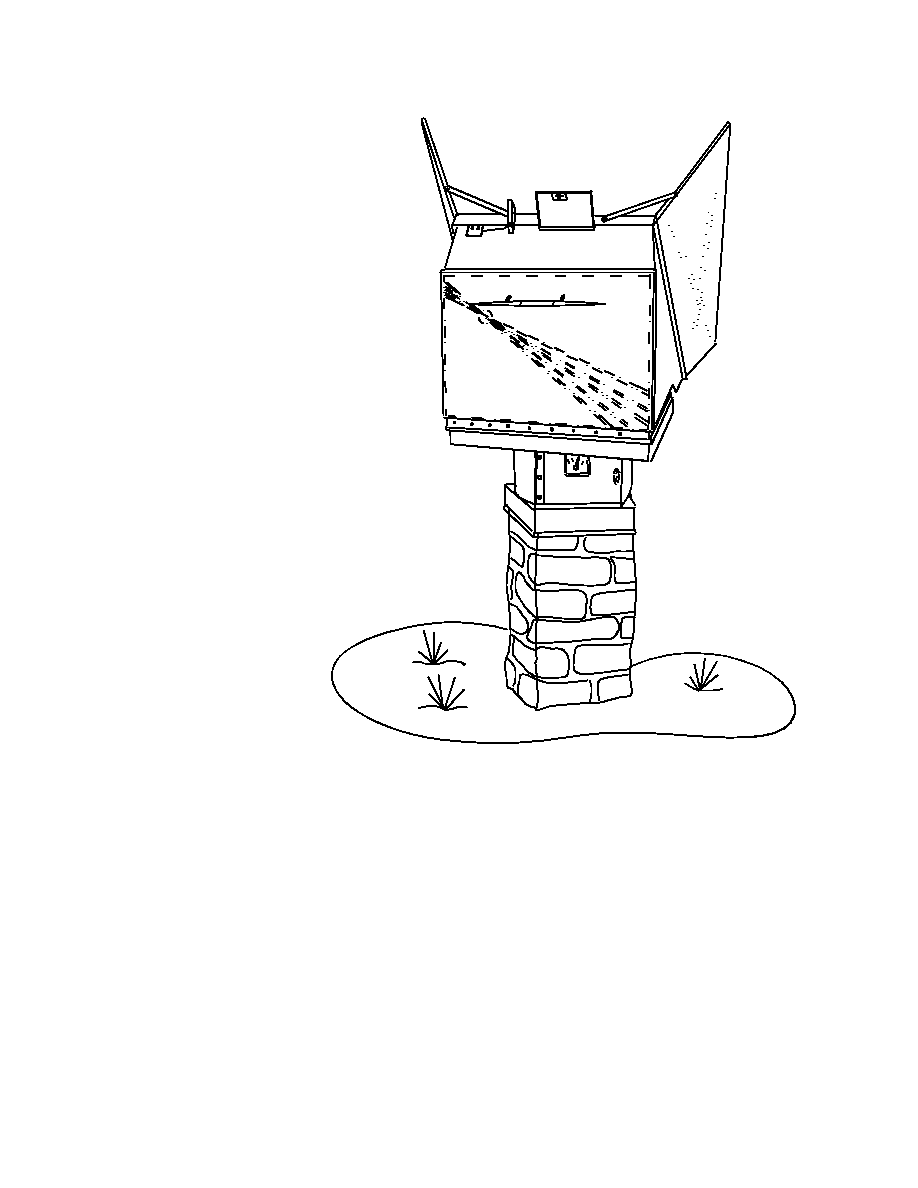

The motor is a critical

part of the design. A 12 to

24 volt DC reversible gear

head motor is needed

which turns at 1 to 5

R.P.M. To further slow

the turning rate of the

oven, a chain and sprocket

with a ratio of about 3 to 1

seems to work very well

for final turning speed of 1

to 1/2 R.P.M. The large

sprocket should be placed

on the shaft connected to

the oven base between

leather washers to form a

slip clutch to protect the drive motor and for safety reasons.

9

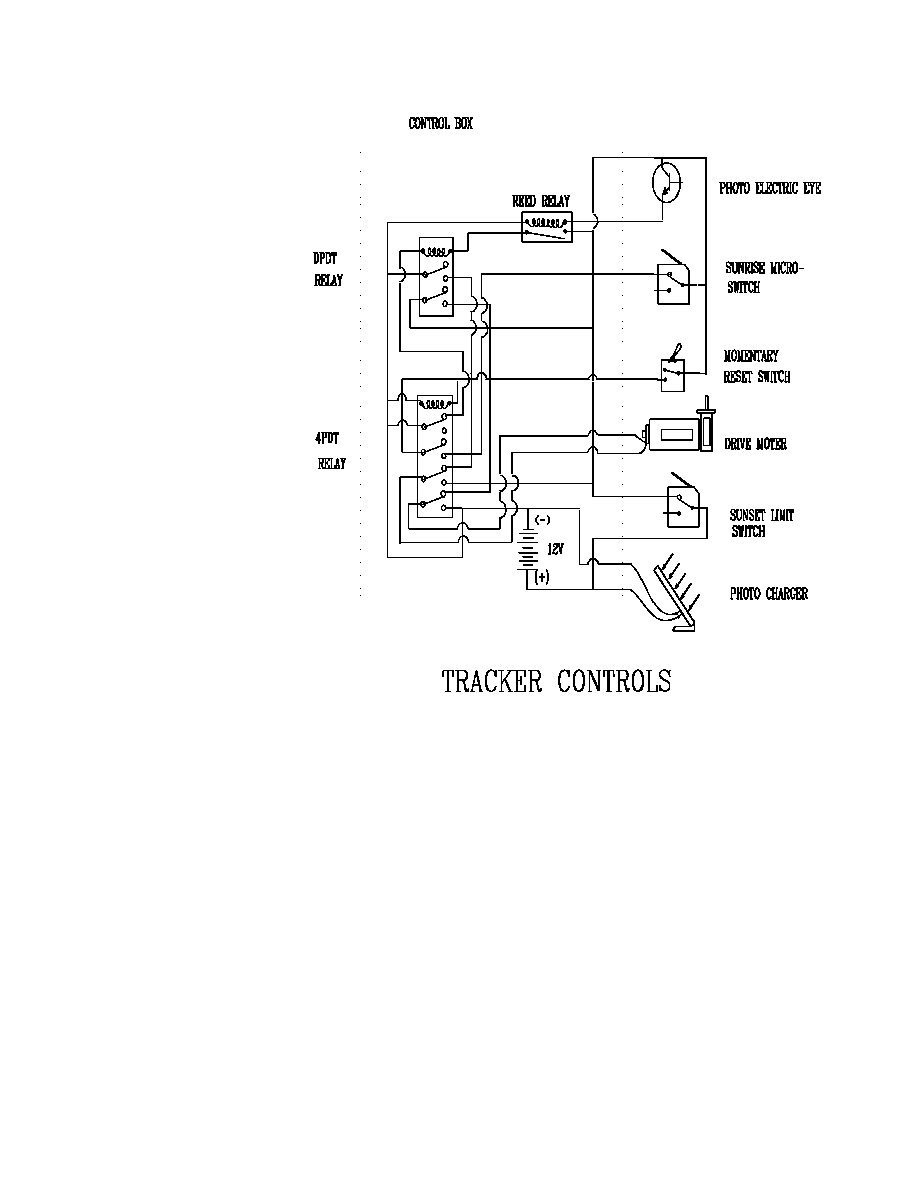

THE TRACKER CONTROLS

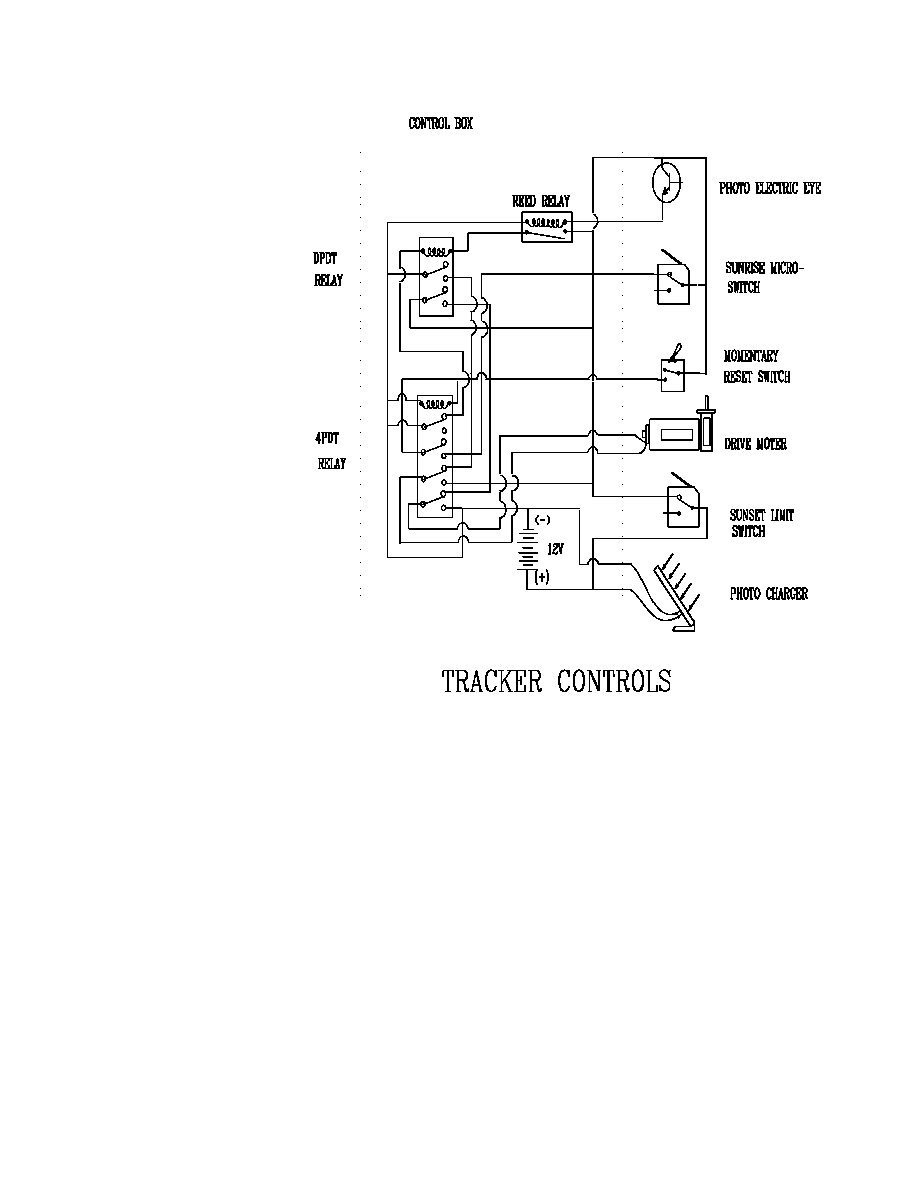

The heart of the

Tracking Solar Oven is the

electronic control. A Very

simple control may be built

from a photo diode

(Electric Eye) and 12 volt

DC relays. Most of the

parts are available at local

radio parts stores.

The photocell battery

charger that works well is

the new thin film, glass-

encased type that produces

18 to 20 volts and

measures only 6 inchs

square. The batteries are

simple AA nickel cadmium

rechargeable cells in series

to produce 12 to 15 volts

at 50 to 80 milliamperes.

The photo diode

(Electric Eye) is really a

photo-transistor using only

the emitter and collector

leads which conduct electricity in the presence of light. A simple shadowbox will shade the electric eye

when the oven is focused on the sun and will cause the motor to stop. At first, the photo diode is far too

sensitive. To adjust the sensitivity black silicone can be dabbed over its surface then removed with a

toothpick until it responds only to direct sunlight. The reset switch will send the motor into reverse until

the sunrise switch is tripped. The oven is now positioned for the next day. A wind-up 12-hour timer

switch on the reset switch will allow timed cooking; it sends the cooker to the sunrise setting when done

and even sounds a buzzer.

Conventional solar trackers are available and can be adapted for use on this or almost any other solar

cooking oven.

10

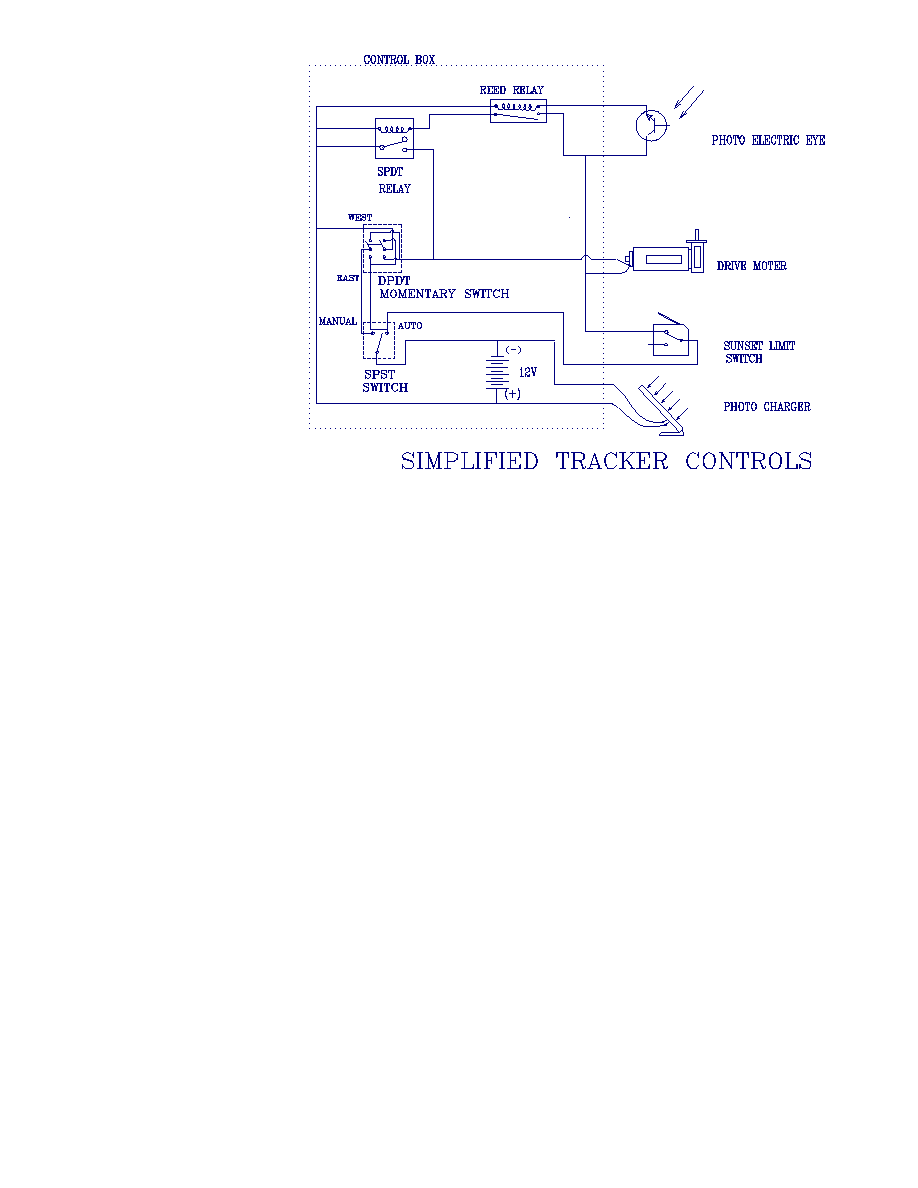

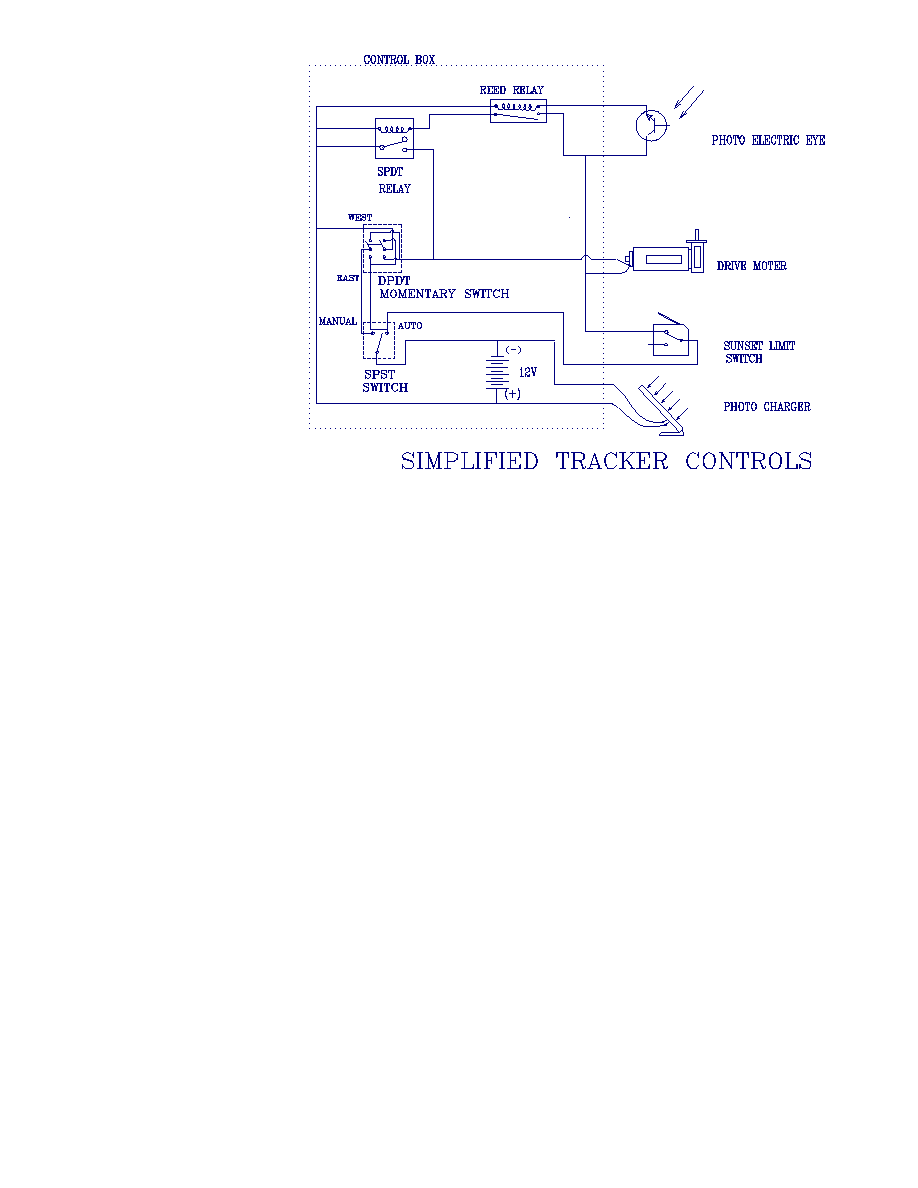

After experiencing

trouble with the tracker

control I disassembled the

controller only to find the

problem was caused by a

sheet metal screw that

penetrated one of the wire

cables. When I

reassembled the controller

I found it works equally

well without all the extra

automatic features. This

simplified version of the

controller is now in use and

serves the purpose.

The material costs are about equally split between the shell, glass and electronics. The total Cost was

approximately $300.

The tracking solar oven is a unique design. The idea for the oven was conceived in 1985 after the

annual solar cooking demonstration in Tucson. The design received the "Clifford C. Sawyer

Achievement" for individual technological achievement in application of engineering principles, American

Consulting Engineers Association, 1993.